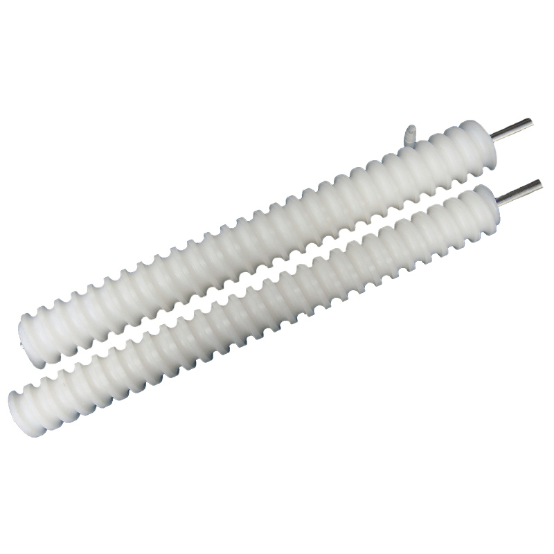

Ultra-high molecular weight polyethylene bottle opener, nylon wheel, the supply of this product is our company supply Coca-Cola bottles dedicated accessories.

custom injection mold custom injection molding custom injection plastic mould custom plastic injection mould inject part injection mold plastic injection

Ultra-high molecular weight polyethylene bottle opener, nylon wheel, the supply of this product is our company supply Coca-Cola bottles dedicated accessories.

Ultra-high molecular weight polyethylene bottle opener, nylon wheel, the supply of this product is our company supply Coca-Cola bottles dedicated accessories.

Ultra-high molecular weight polyethylene (uhmw-pe) is the average molecular weight in 9.2 million above the linear structure of polyethylene (relative molecular weight is only ordinary polyethylene (2-300000). High relative molecular weight, and given the extraordinary performance, make it is a kind of excellent comprehensive performance, moderate price of new thermoplastic engineering plastic, it almost collected all kinds of plastic is superior performance, its wear resistance, corrosion resistance, low temperature resistance, self-lubrication and impact resistance properties of five aspects, such as are among the top of the existing engineering plastics! Guangzhou grace plastic products (group) co., LTD. \'family can provide full specifications of uhmw-pe sheet bar and tube, at the same time also can provide for customized services of uhmw-pe precision machined parts. Our company production of uhmw-pe materials (100% original German imports of raw materials production) has the following eight features:

![N~R_@X63ALJ@1M[{8{]U]OG N~R_@X63ALJ@1M[{8{]U]OG](/uploadfile/upload/2017-08/08/NR_X63ALJ1M8UOG.png) 1. The wear resistance of the plastic crown, seven times higher than the carbon steel and four times higher than teflon.

1. The wear resistance of the plastic crown, seven times higher than the carbon steel and four times higher than teflon.

2. Plastic impact strength listed in the first place, more than 2 times the polycarbonate, 5 times higher than ABS.

3. The self-lubricating performance of F4, than steel and brass add lubricating oil after high lubricity.

4. Corrosion resistance: in a certain temperature and humidity within the scope of ability, all kinds of corrosive medium and the effect of organic solvent medium, high chemical stability.

5. Not sticky, surface of products with other material is not easy, strong adhesion resistance.

6. Impact resistance, impact energy absorption of all the plastic top, 10 times that of nylon 66, 8 times of ptfe.

Low temperature resistance, in liquid nitrogen (196 ℃), still has the ductility, the toughness at low temperature is done not have in all plastic performance.

8. Complete health non-toxic: is the drug and food (FDA) and the United States department of agriculture (USDA) allows for contact with the food and drug materials.

Scope of application:

Scope of application:

Uhmw-pe as a 21st century can be used instead of carbon steel, stainless steel, bronze and other metal new material, has been plastic products group co., LTD. Guangzhou grace \'family used to make all kinds of precision machinery parts and components, including including food machinery gear, worm gear, worm, bearing, bearing, the star wheel, valve, pump, arc guide rail.

Do in chemical pumps, valves, dampers, filter plate, pressure parts, connectors, filter.

Surgical parts can also be used for short form, artificial joints and birth control implants.

In sports do skating, ground floor, skis, snow mobile spare parts and other products, and plastic products group co., LTD. Guangzhou grace \'family and success will uhmw-pe materials used in: petroleum, chemical industry, light industry, military industry, machinery, electric power, medical, aviation, automobile, textile, mining, Bridges, food machinery, electronic electrical, instrumentation, transportation, building materials, plastic rubber and scientific research departments such as trade, go deep into the People\'s Daily life in various fields.

And obtained the good social efficiency and the product reputation, favored by the majority of users directly.

Oil-bearing nylon is plastic products co., LTD. Guangzhou grace \'family in the late 90 s by introducing advanced technology in the UK and the successful development of new products.

It is in the true sense of self-lubricating nylon, formed in the process of casting liquid lubrication system, make the oil nylon 50% lower than the average friction coefficient of nylon, 10 times and wear resistance can be improved, is specially designed for not lubrication, high load and low speed parts and development, with obviously improve the service life of bearing oil nylon, six times that of the ordinary nylon bearing life and phosphor bronze bearing life 25 times!

Nylon contains lubricant oil does not leak, adsorption, and exhausted, also do not need to add.

Lubricant oil in nylon uniform distribution, to ensure the parts during the entire service performance stability, improved the wear rate, sliding friction properties.

Oil-bearing nylon greatly widened the scope of application of nylon, especially for some parts can\'t lubrication.