best performance abrasion resistance high hardness in the surface

Assist global clients in engineering material,professional custom injection molding service,CNC machining service.We can provide you with one-stop solutions.

Those plastics materials like UHMW-PE , MY Nylon , PA6 , POM , HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic , PEEK , PPS , PTFE , PVDF , PAI , PEI , PSU , PI , PBI etc., they have different characteristic ! For example flowing temperature , crystallization speed , heat dispense , viscosity , pressure, speed , deformation and stripping .

Thanks for clients all along support , we gain lots of successful and failure cases , those experiences we store in database , which guide our new staff avoid same mistake. Today our comprehensive service from industrial design, mold design and manufacturing, volume production and production is based on an end-to-end quality assurance system that delivers an efficient, cost-saving, turnkey solution in plastic injection molding manufacturing.

Our mold team uses the lasted new version software design programs: UG, ProE, SolidWorks, Catia, Rhino etc., you can send any type of drawings xmt,step,vad or .iges. We also give you service is reverse engineering, we can follow your sample to create a completely new 3d drawings and the molds.

Our clients include medical industry, automobile, electronics industry, consume plastic products, etc., Our skilled technician and mould maker specialists work with each individual client and use the best material available for each application, Guides your project through each phase of development to save you time and money. We will explain whole process efficiently in five main stages: the production of the technical preparation stage, the preparation stage of raw materials, parts and components processing stage, assembly and commissioning phase trial identification stage. It is clear and confident to achieve success .

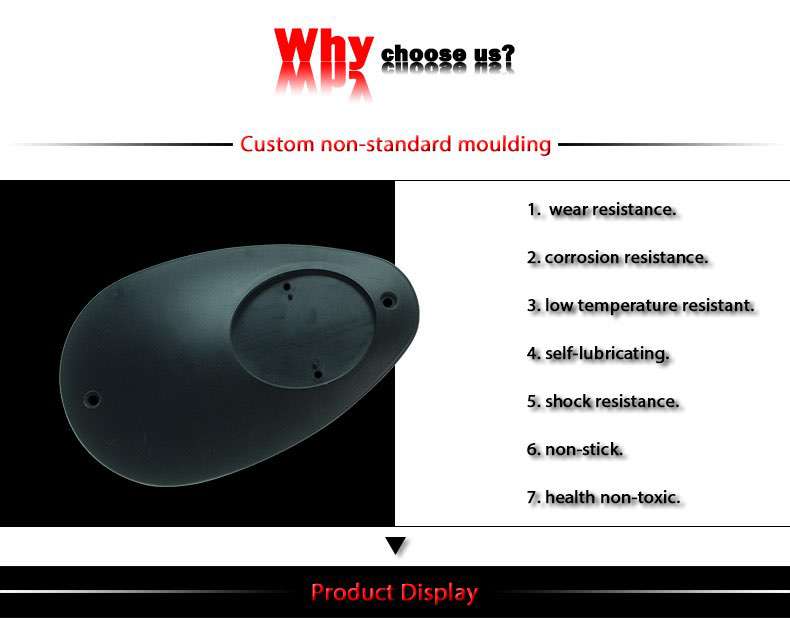

Description:

Nylon PA6 Sheets & Rods that made the with 100% Virgin Raw Material by Guangzhou Engineering Plastics Industries (Group) Company, has the best performance, such as: very tough, even at low temperatures, and high hardness in the surface, toughness, mechanical lower shock, and abrasion resistance. Combined with these characteristics and good insulation, and chemical properties, it has become common-level materials. Its widely used in a variety of mechanical structures and spare parts. Nylon PA6 products that made by Guangzhou Engineering Plastics Industries (Group) Company, has the higher hardness, rigidity, a good resistance to wear and heat deflection temperature.

Advantages:

1. Good Tensile strength;

2. High impact and notching impact strength;

3. High heat deflection temperature ;

4. High strength and stiffness;

5. Good glide and limp home characters;

6. Good chemical stability against organic solvents and fuels;

7. Resistant to thermal aging (applicable temperature between -50°C and 110°C;

8. Size alternation by humidity absorption must be considered;

Application:

1. Nylon PA6 Products that made by Guangzhou Engineering Plastics Industries (Group) Company is widely substituted for wear parts of mechanical equipment, or used as quick-wear parts of equipment instead of copper and alloy;

2. Shaft sleeve, bearing bush, lining, lining plate, gear;

3. Worm gear, roller copper guide rail, piston ring, seal ring, slide block;

4. Spheric bowl, impeller, blade, cam, nut, valve plate,

5. Pipe, stuffing box, rack, belt pulley, pump rotor, etc.