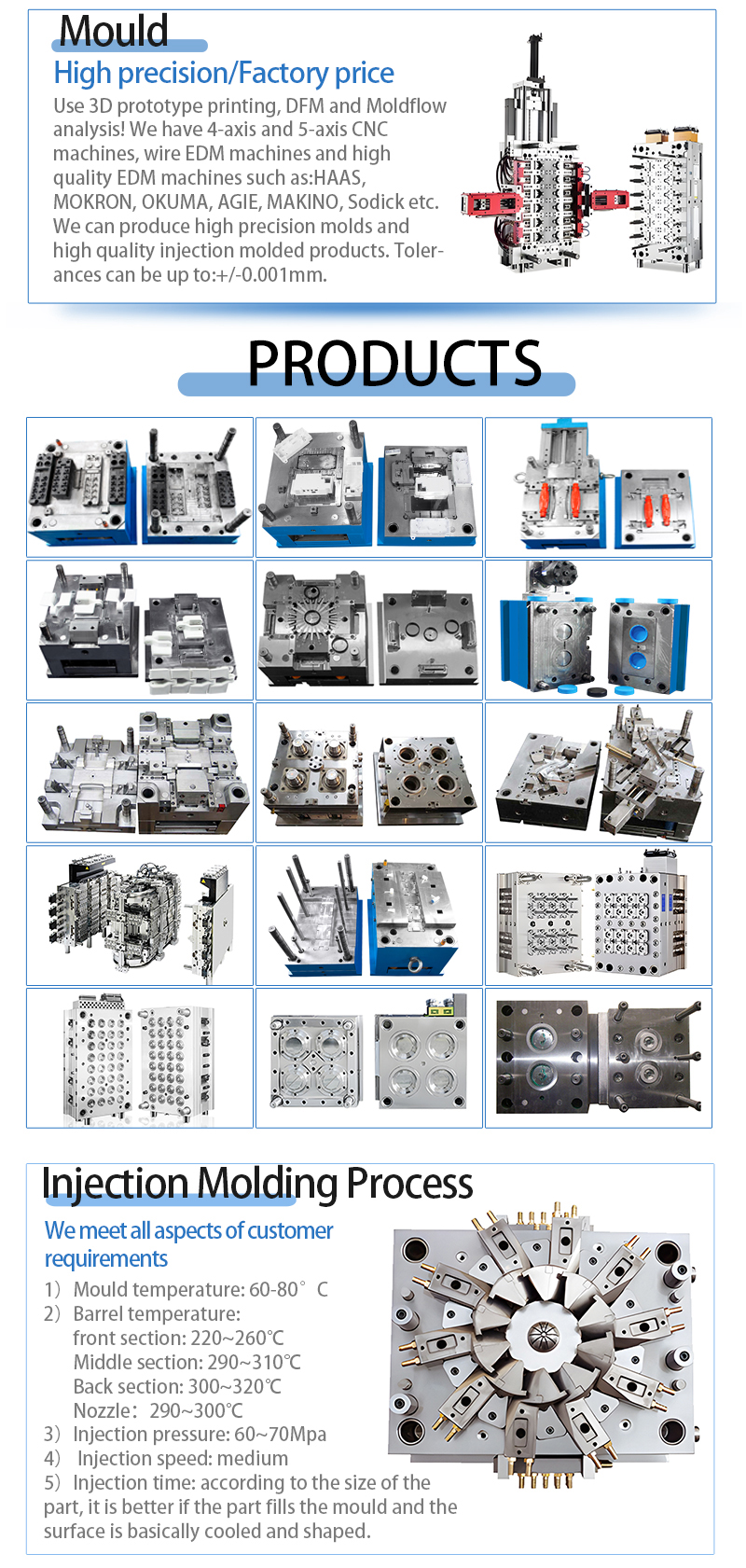

Leading Global Injection Molding Supplier Assist global clients in professional custom injection molding service,CNC machining service and engineering material,.We can provide you with one-stop solutions. Main Product: 1.Custom made all kinds p

Automotive Moulding Injection

Leading Global Injection Molding Supplier Assist global clients in professional custom injection molding service,CNC machining service and engineering material,.We can provide you with one-stop solutions.

Main Product:

1.Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble) .

2.Our engineering plastics products: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

How to get a quotation:

1. Prepare a picture or 3D drawings;

2. You want the product material;

3. Quantity per order, estimated annual requirements send to our email: [email protected], ask us TM online, We can offer you quickly and give you the professional advise to save mold cost and keep high quality.

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture,Sanblasting,Gilding, UV Painting… |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC,PMMA(Acrylic),TRU,EPDM,NBR,Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Runner System | Hot runner and cold runner |

| Mould Cavity | Single cavity, multi-cavity |

Injection Process

Why choose us

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production

Our Factory

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

FAQ

Q1. Can only samples be produced?

A1. Yes.

Q2. What is the accuracy of the products processed by the drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What areyour processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine.

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,electroplating, etc.