Injection molding production of large household appliances plastic shell injection mold manufacturers plastic mold ABS

Why injection Moulding Injection Parts ?

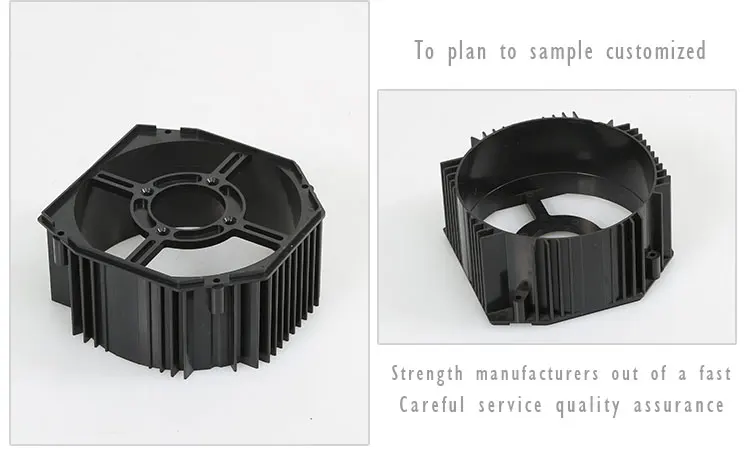

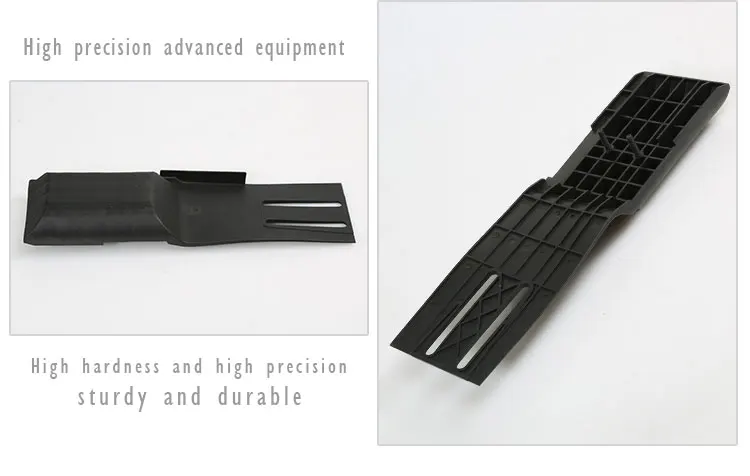

For quality , injection is better, the smoothness and flatness can be done on the mold, and the strength is also good. Some transfers during mechanical processing, the sharp edges may be difficult to process beautifully . But mass injection need big quantity to open mould to decrease unit price because of expensive mould .

Injection molding production of large household appliances plastic shell injection mold manufacturers plastic mold ABS

Guangzhou Engineering Plastics Industries (Group)Company,Plastic injection molding factory provides professional plastic mold injection technology,canproduce a variety of injection mold injection molding,Mould Steel is made by:S136H,NAk80,718H,SKD61 Heat hard,H13 Heat hard.420(Heat hard)and so on!

Injection Materials:PA6,PA66,Pa66+GF,POM,ABS,Nylon,UPE,PE,TPE,PP,PC,PVC,PET,PMMA,PPS,PEEK,PAI,etc.

Notice:All of the specific size,color,quantily and materials can be customized according to the customer’S requirements.

|

Name |

Injection molding production of large household appliances plastic shell injection mold manufacturers plastic mold ABS |

|

Material |

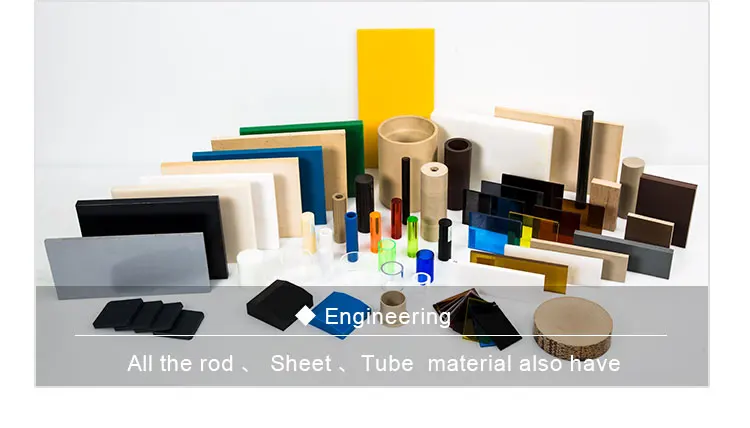

Acrylic,PC,PVC,Nylon,PEEK,PU,PA,POM,PE,UPE,PTFE,etc. |

|

Color |

White,black,green,nature,blue,yellow,etc |

|

Diameter |

5-200mm,or customized |

|

Condition |

In stock/Made to order |

|

Shape |

As per your drawing |

|

Certification |

ISO9001,SGS,Test Report,RoSH |

|

Free Sample |

Available |

|

Shape |

Sheet, rod, tube, gear, rack,pulley, guide rail, Plastics fittings,and so on |

|

Advantage |

One stop procurement |

|

Packing |

Plastic bags,Cartons,Wodden case,Pallet,Container,ect. |

|

Other |

24 hours instant and comfortable customer service. |

|

Shipping status notification during delivery. |

|

|

Regular notification of new styles & hot selling styles. |

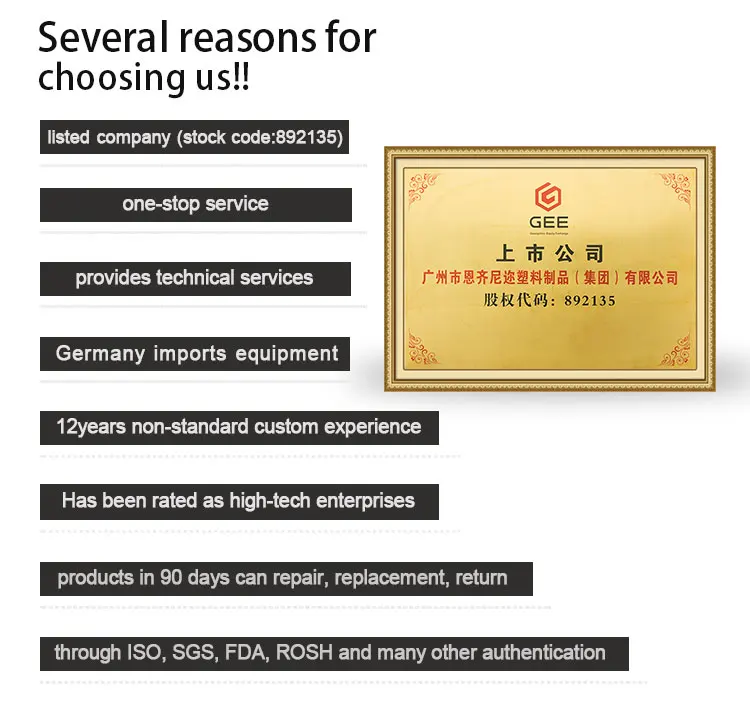

Guangzhou Engineering Plastics Industries (Group) co., LTD., established in January 2009, is a professional production of "engineering plastics accessories" high-tech enterprises. The company has a complete set of imported production equipment and numerical control processing equipment, processing means is advanced, technical force is abundant. Product best-selling Europe and America, southeast Asia, the Middle East, Africa and Hong Kong, Taiwan and other countries and regions, by domestic and foreign customers consistent high praise.

Company\'s main products: UHMW-PE,POM,MC Nylon,Oil Nylon,HDPE,ABS,PBT,PET,PVC,PC,PU,PP,PTFE,PVDF,PEI,PSU,PPS,PEEK,PAI,PI,PBI .

company wide range of accessories processing conditions, such as mass customization production ability, exquisite manufacturing technology and advanced production equipment, professional technical advice and after-sales service of products.

Companies strictly enforce the ISO9001 (2008) international quality certification system, the product quality conforms to the eu RoHS standard.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

2. Q: How long is your delivery time?

A: According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you.

3. Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

4. Q: What are the after-sale services?

A: In case of quality problems, the package can be exchanged within 90 days.