Factory direct supply PVC ABS PP medical accessories custom PVC ABS PP injection molding parts

Factory direct supply PVC ABS PP medical accessories custom PVC ABS PP injection molding parts

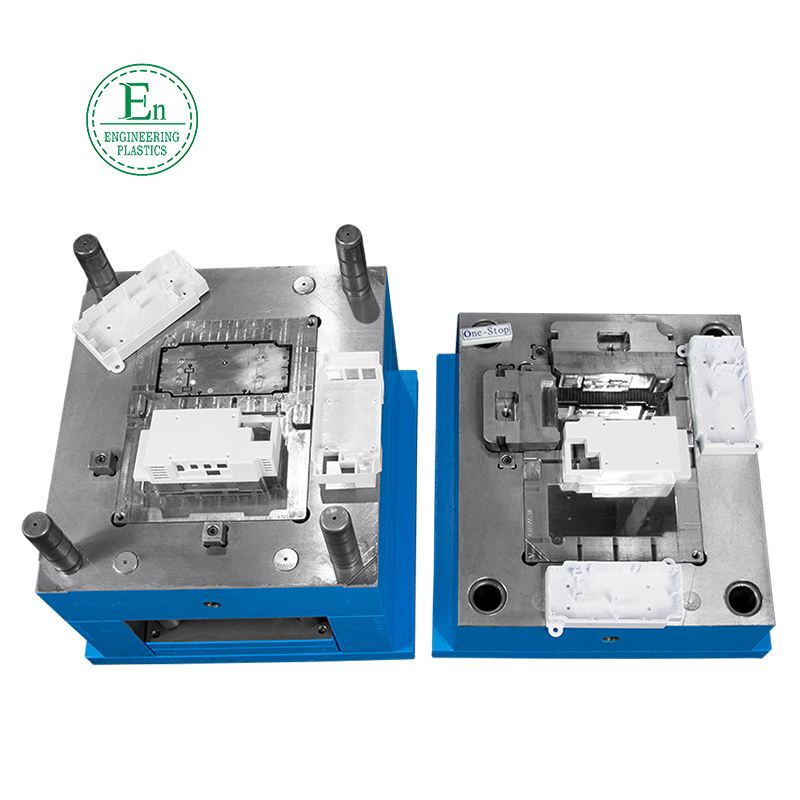

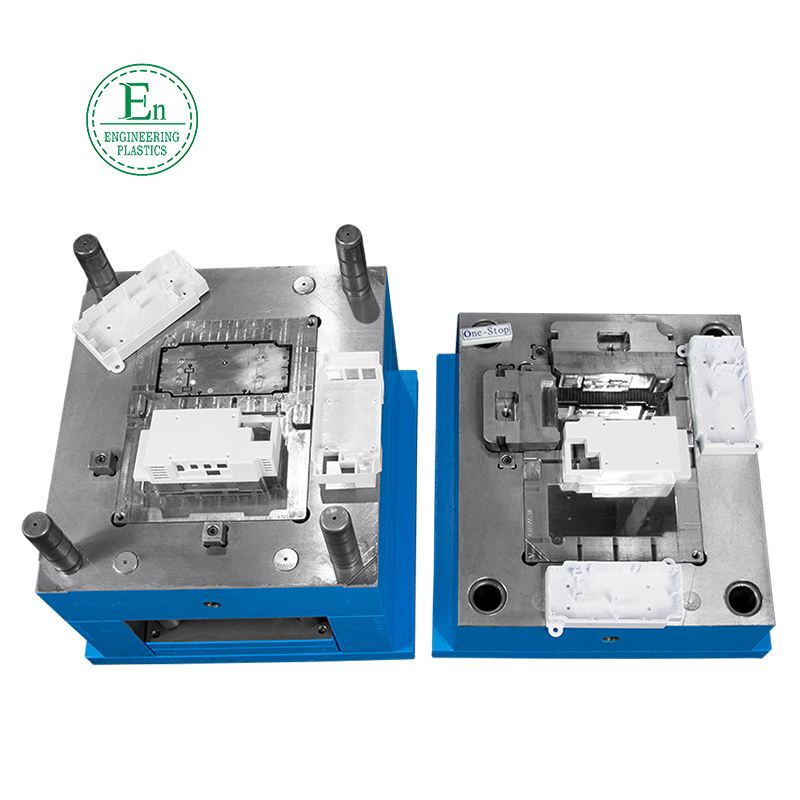

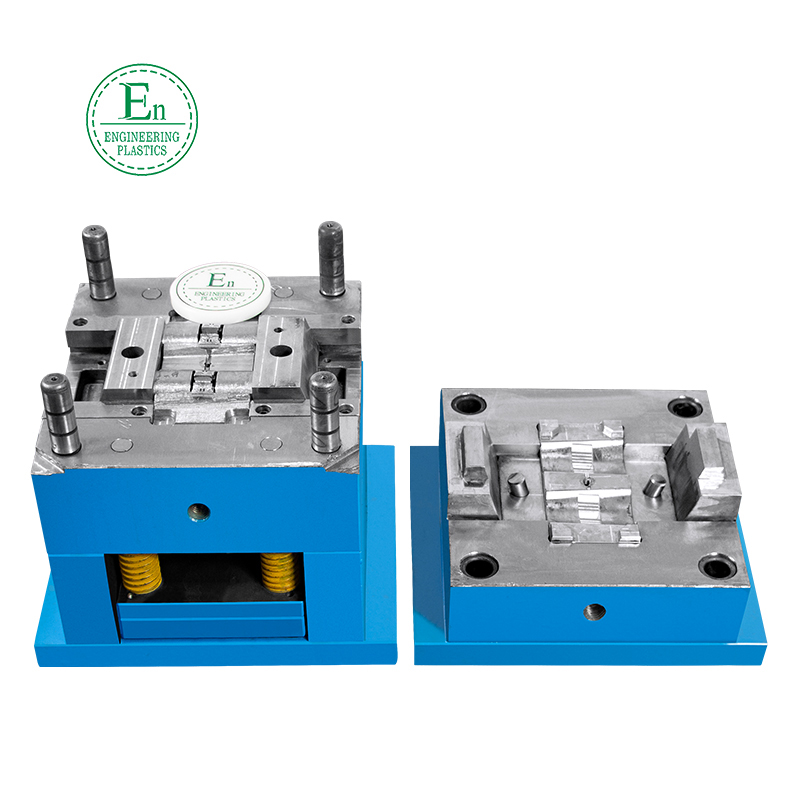

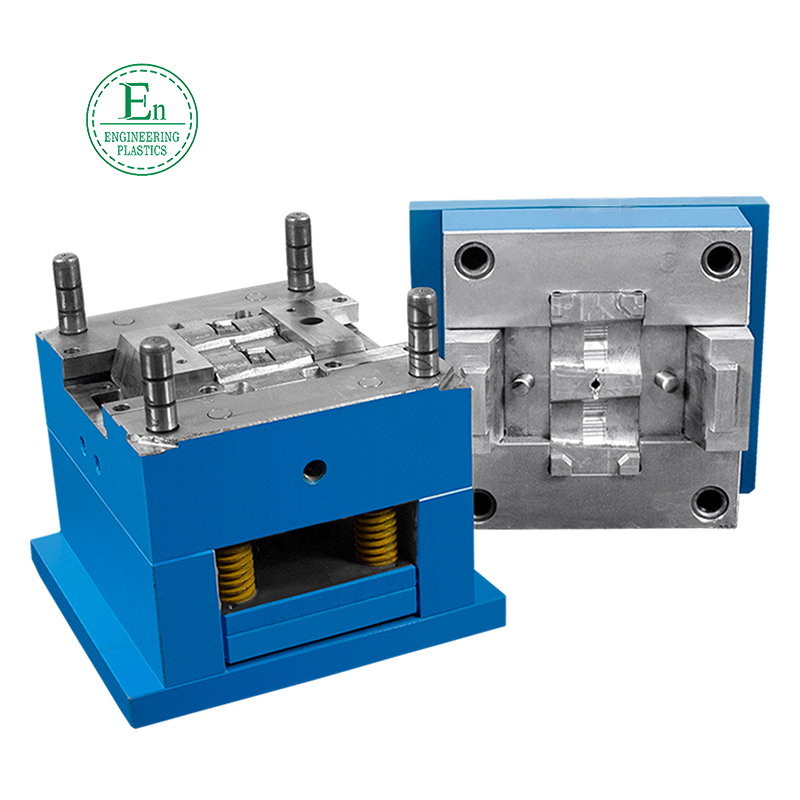

We have dozens of large injection molding machines and outstanding mold engineers, can produce various

high precise plastic products, which can be used in machinery, automotive, mining, energy, medical and building

industries, etc..

|

Product Description |

ODM plastic injection molding |

|

Plastic Materials: |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

|

Standard: |

ISO9001:2008 |

|

Other materials: |

Rubber, Silicone rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

|

Quality: |

RoSH and SGS standard |

|

Feature: |

Non marking and Non flash |

|

Size: |

According to your 2D, 3D Drawing |

|

Color,Quantity,Unit price,Tooling cost,Tooling size: |

To be discussed |

|

Package: |

Standard exported Wooden box packed, Fumigation process(upon required) |

|

Export Country: |

Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

|

Experience: |

More than 10 years experience in plastic injection mold making and plastic products produce. |

|

To be discussed |

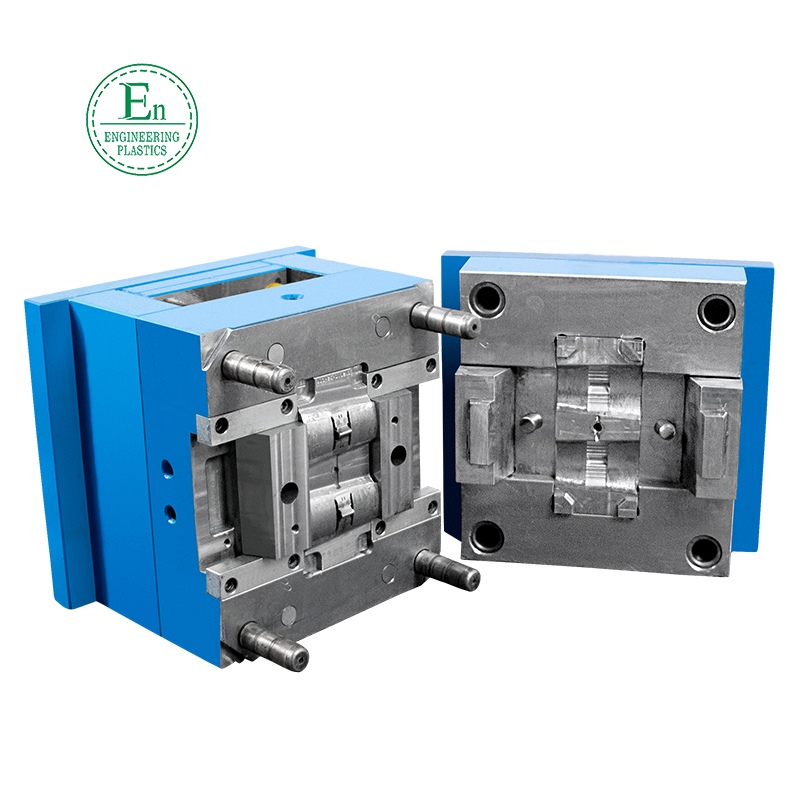

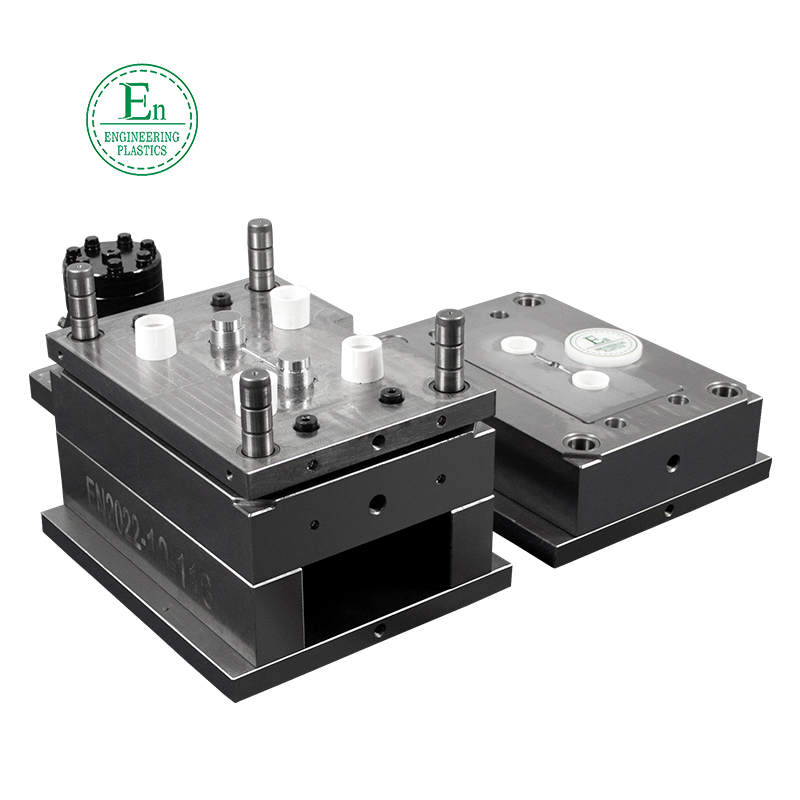

In-Mold Decoration, Injection Mould, Plastic Mold, Over mould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, |

|

Mould Base: |

HASCO Standard, European Standard, World Standard |

|

Mould Base Material: |

LKM, FUTA, HASCO, DME,...etc. Or as per Customer\'s requirement. |

|

Surface Finish: |

Texture(MT standard), High gloss polishing |

|

Cavity/ Core Steel: |

P20, 2311, H718, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

|

Hot/ Cold Runner |

HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

|

Mould Life: |

5,000 to 1,000,000 Shots. (According to your working environment.) |

|

Design & Program Software: |

CAD, CAM, CAE, Pro-E, UG, Soild works, Mold flow, CATIA....etc. |

|

Equipment: |

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T |

Why choose us?

1. OEM/ODM services

2. Low MOQ & reasonable price and high precision

3. Professional mold design and manufacturing service

4. Provide one-stop procurement, assembly finished product service

5. Eco-friendly production, strict quality and 24 hours after-sale service

Our Advantage:

1.Application expertise

2.Custom R&D program coordination

3.Competitive price

4.Continuance service and support

5.Diversified rich experienced skilled workers

6.Quality, reliability and long product life

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.