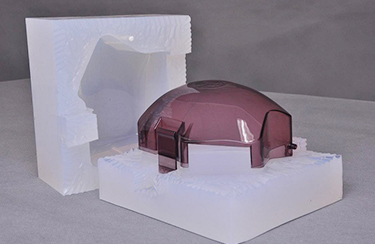

Need to quickly test out the market with low-volume parts? Or want to create large quantities of production parts? Then you can't go wrong with our plastic injection molding service. At Guangdong Enineering Pastics Industries (Group)Co. Ltd., we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability, functionality and marketing, fast. We also offer plastic injection molding for your high-volume production needs.

we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability, functionality and marketing, fast.

Need to quickly test out the market with low-volume parts? Or want to create large quantities of production parts? Then you can't go wrong with our plastic injection molding service. At Guangdong Enineering Pastics Industries (Group)Co. Ltd., we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability, functionality and marketing, fast. We also offer plastic injection molding for your high-volume production needs.

Why We is your best option for plastic injection molding

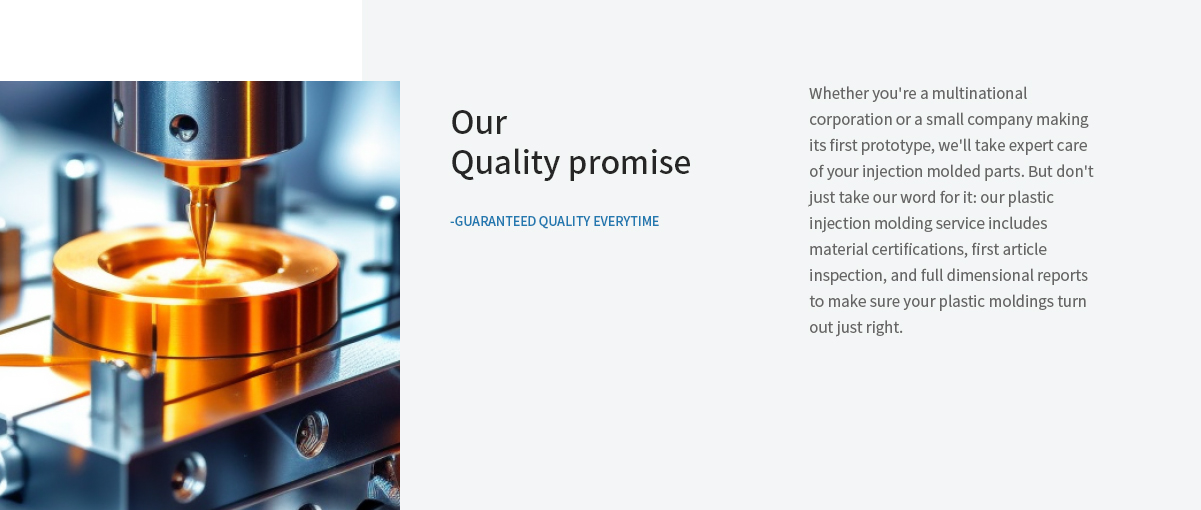

With years of experience creating molded plastic parts for our customers, Guangdong Enineering Pastics Industries (Group)Co. Ltd.provides many advantages over other companies. We offer a truly end-to end plastic injection molding service, from design to production, always guaranteeing the highest quality.

Here are four reasons why Guangdong Enineering Pastics Industries (Group)Co. Ltd. is your best option for plastic injection molding一whatever the parts, whatever the scale.

See why Our Customers love us

Additional Plastic Injection Molding Options

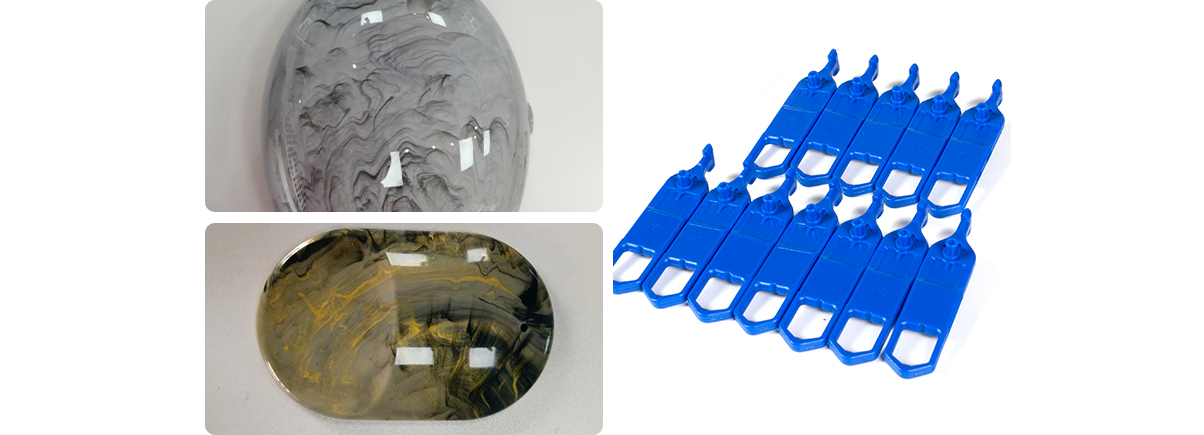

Overmolding

Overmolding is a form of custom plastic injection molding during which the plastic injection molding company creates a part from multiple materials. The process adds an injection molded layer of material over an existing injection molded workpiece, producing chemically bonded parts made from multiple materials. The overmolding process can be used to build layered parts from scratch or to add a resistant outer layer to existing plastic parts and tools, providing a more rugged exterior. Toothbrushes consisting of a solid plastic body and rubberized grip are a common example of an overmolded product.

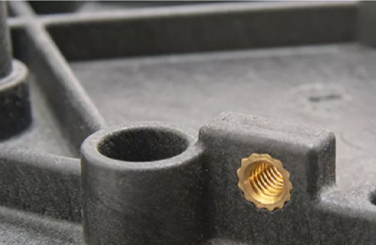

Insert Molding

Insert molding is similar to overmolding, but the substrate is not necessarily plastic and does not have to be produced via injection molding. For example, insert molding can be used to add a plastic coating toa pre- fabricated metal part like a blade or threaded insert. Common parts made by insert molding include sharp handheld tools, such as scalpels, which consist of a metal blade partially housed within a plastic handle. Insert molding is also frequently used to create products that incorporate bushings, clips, and fasteners.

Prototype Molding & Mass Production Molding

Delivered fast with 4 simple steps

Injection Molding Plastic

Our plastic injection molding service supports the manufacture of parts in a range of molding materials. These include rigid plastics like ABS, flexible plastics like TPE, and mixed materials like PC-ABS. We can also obtain specialty materials and create custom material and pigment blends to suit your order.

Rigid plastics

The majority of injection molded parts are made from rigid thermoplastics. These include inexpensive and versatile plastics like ABS and PP, as well as naturally transparent plastics like PC and acrylic and high-strength plastics like POM. Other rigid plastics for injection molding include nylon, PET, and PS.

Injection molding pellets can also be mixed with non-plastics, leading to composite injection molding materials. Such composites include glass-filled polyamide, which is very hard and strong with good creep resistance, and glass-filled polycarbonate, which offers high strength and stiffness with low thermal expansion.

Plastic Injection Molding Finishes

The most convenient way to apply surface finishes to moldings is to perform any necessary finishing on the metal mold. In this way, we can give the moldings different surface finishes such as matte, high-gloss, and various textures. Secondary finishes - applied to the finished moldings - are also an option.

Matte

Plastic injection molding companies like Guangdong Enineering Pastics Industries (Group)Co. Ltd. can give a consistent matte finish to plastic injection molded parts - soft grip handles, for example - by carrying out techniques like sandblasting,chemical etching and EDM on the metal mold. The surface roughness of matte moldings typically ranges between 0.40 and 18.00 Ra um.

It is possible to make high-shine molded parts with a gloss finish — electronics housings, for example — using post-processing techniques like sanding, polishing, and diamond buffing. The lowest level of surface roughness for acrylic molded parts is around 0.012 Ra µm.

Learn More About Plastic Injection Molding

What is plastic injection molding

Plastic injection molding is a manufacturing process mainly used to make plastic parts in large quantities. Used by many industries for a wide variety of parts, plastic injection molding produces more thermoplastic parts per year than any other plastic manufacturing process.

The plastic injection process requires a metal mold and an injection molding machine. Plastic pellets are heated to melting point, then forced into the mold, where the material cools and soldifies, assuming the shape of the mold cavity.

The most common materials for plastic injection molding are thermoplastics such as ABS, nylon, and acrylic. However, it is also possible to mold thermosets and elastomers.

Plastic injection molding can produce parts in a range of sizes, from bottle caps to large automotive panels, but it is best suited to thin-walled parts, because thick sections of molded plastic are more likely to deform as they cool down inside the mold.

FAQs

What plastics can you use with injection molding?

Injection molding plastics can be rigid, flexible, or combinations of multiple materials. This unmatched versatility is what makes custom plastic injection molding so popular and suitable for some of the most demanding industries in the world.

What is the process behind plastic injection molding?

The plastic injection molding company melts down plastic pellets then injects the liquid into a mold, where the material cools and assumes the form of the mold cavity. The process allows for high precision, tight tolerances, and excellent repeatability.

Why should I use a plastic injection molding service?

Injection molding is one of the most affordable ways to manufacture large quantities of parts, especially for bigger production runs. Even though designing and creating the mold can take time, after that, the process becomes very affordable and efficient.