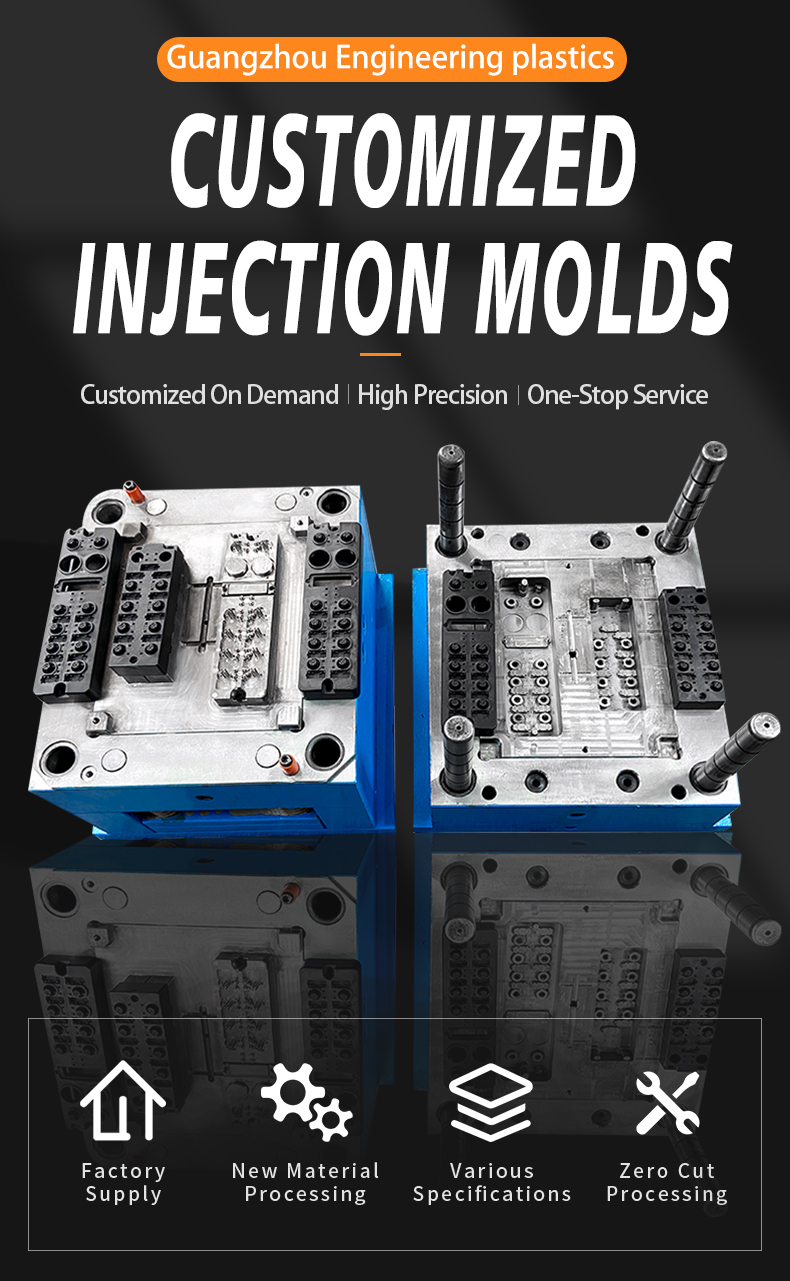

Plastic manufacturing injection molding ABS injection plastic product

Plastic manufacturing injection molding ABS injection plastic product

Guangdong Engineering Plastics Industries (Group) Co.,Ltd. provides OEM and ODM the sleeve bushing

products, if you want to learn more, please feel free to contact our sales manager Lydia Gong and email

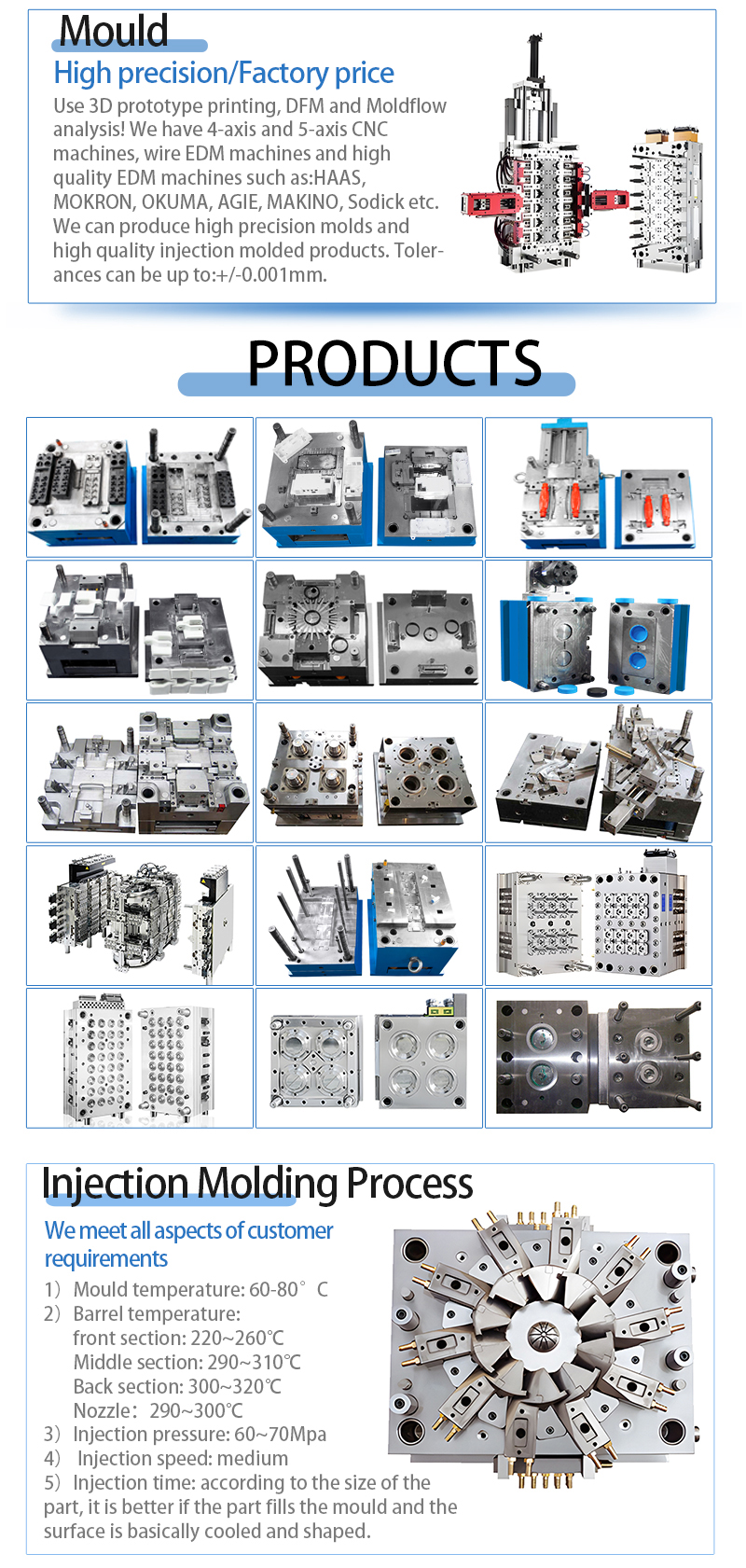

Injection molding is a forming process using molds. Materials such as synthetic resins (plastics) are heated and

melted, and then sent to the mold where they are cooled to form the designed shape. Due to the resemblance

to the process of injecting fluids using a syringe, this process is called injection molding.

The flow of the process is as follows: Materials are melted and poured into the mold, where they harden, and

then the products are taken out and finished.

With injection molding, diversely shaped parts, including those with complex shapes, can be continuously and

quickly manufactured in large volumes. Therefore, injection molding is used to manufacture commodities and

products in a wide range of industries.

|

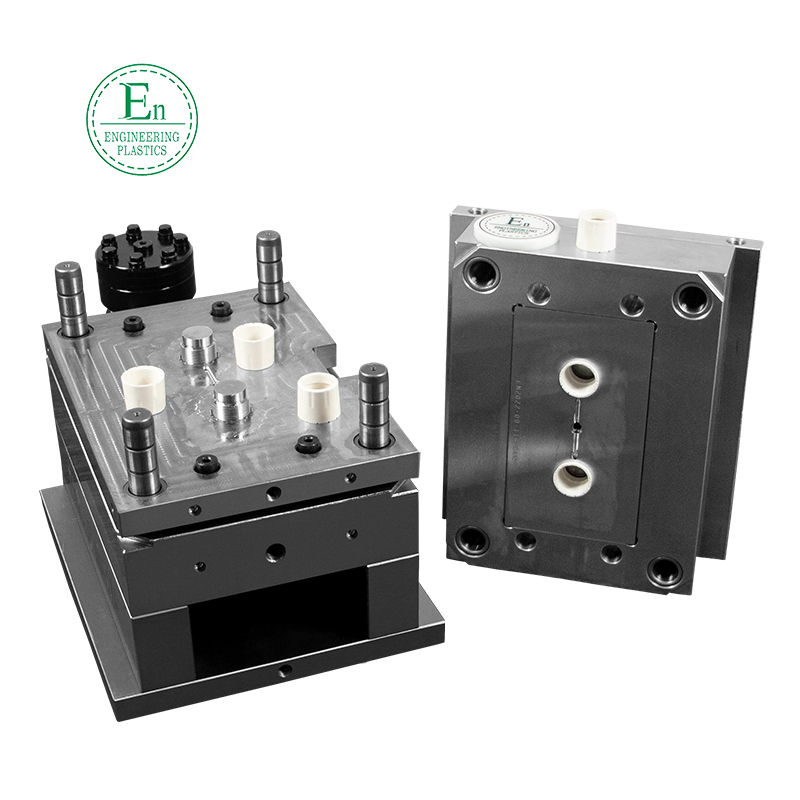

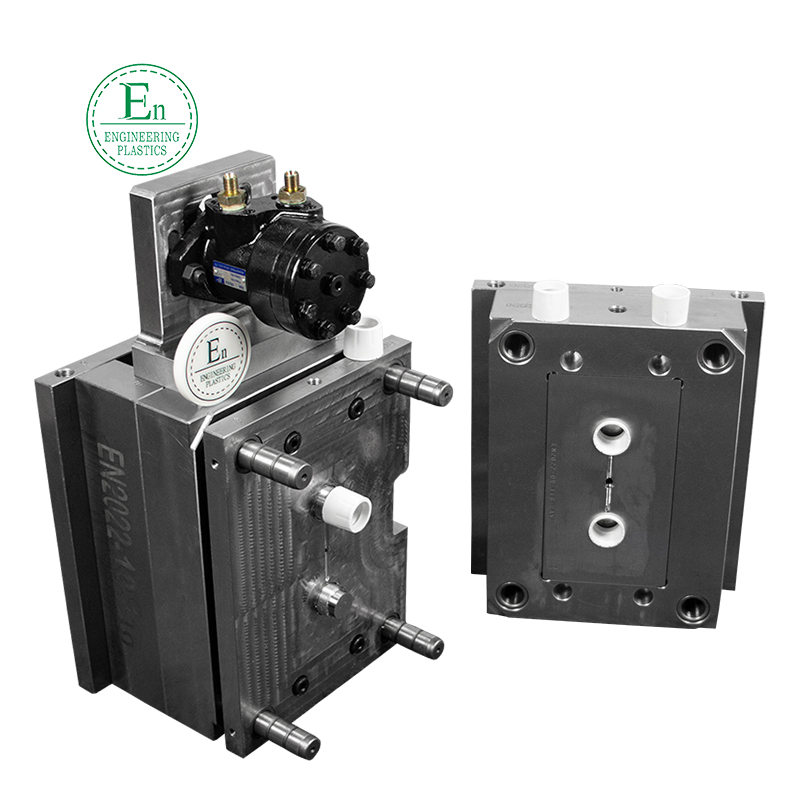

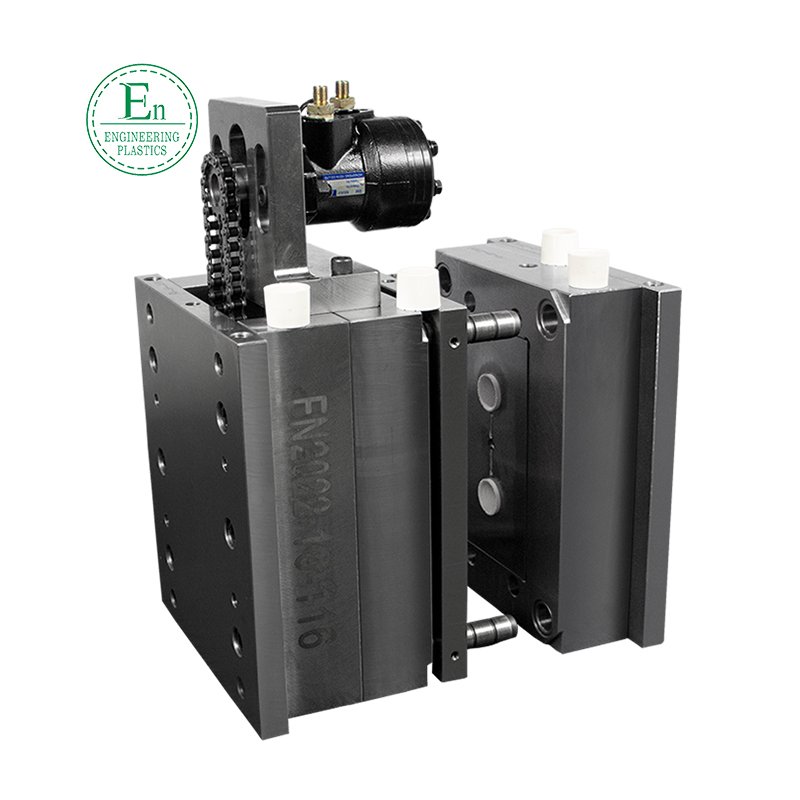

Product Name |

High Quality Plastic Injection Mold and Molding Manufacturer |

|

Plastic Material |

ABS, PP, PC, PVC, POM, TPU, PC, PEEK,HDPE,NYLON, Silicone, Rubber, etc |

|

Mould Precision |

+/-0.01mm |

|

Mould Cavity |

Single cavity, multi-cavity. |

|

Runner System |

Hot runner and cold runner |

|

Sureface Treatment |

Polishing/smooth,texture/frosted, painting, plating, printing , etc. |

|

File Format |

STEP, STP, STL, X-T, IGS, PDF,JPG,etc. |

|

Custom Feature |

According to your 2D/3D Drawing or sample provided |

|

Our Equipments |

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 30-1400T available. |

|

Quality Assurance |

ISO9001: 2015, SGS, ROHS, TUV,etc |

|

Main Field |

Home appliance, Medical device, Electronic device, Automotive parts, Tele-communication, Lighting control equipment, digital device, Robots, etc. |

How do you ensure product quality?

As you can see, we apply assessment, planning, monitor at every single process.

1) Apply APQP Product development process

2) Lay emphasis on prevention and planning

3) Once a year ISO9001, IATF 16949 audit and refreshing

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.