Testing and evaluation of injection molding materials Once a suitable injection molding material has been selected, it is imperative to conduct thorough testing and evaluation to ensure that it meets the desired performance

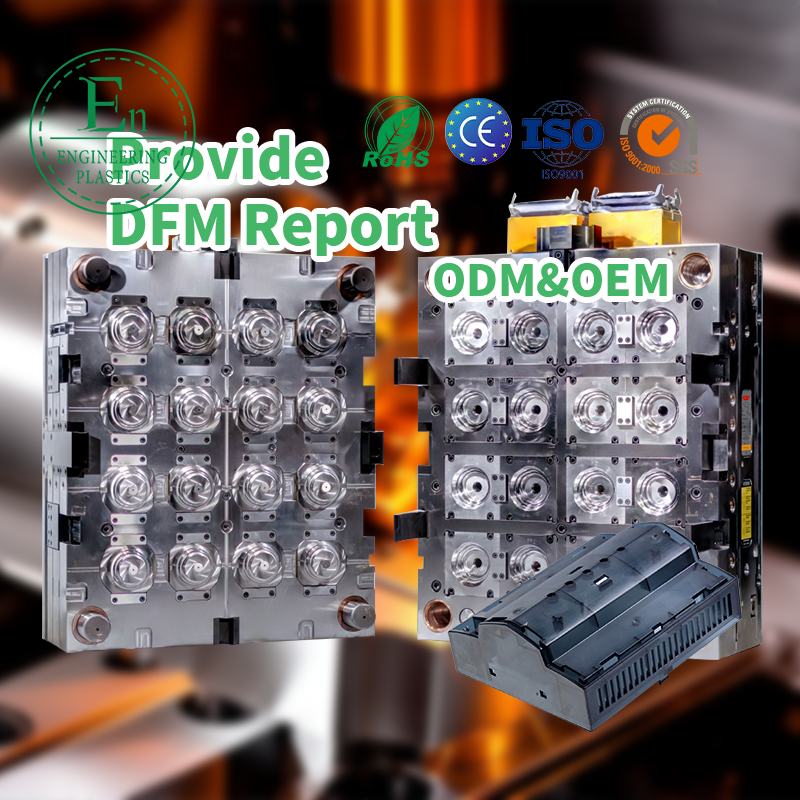

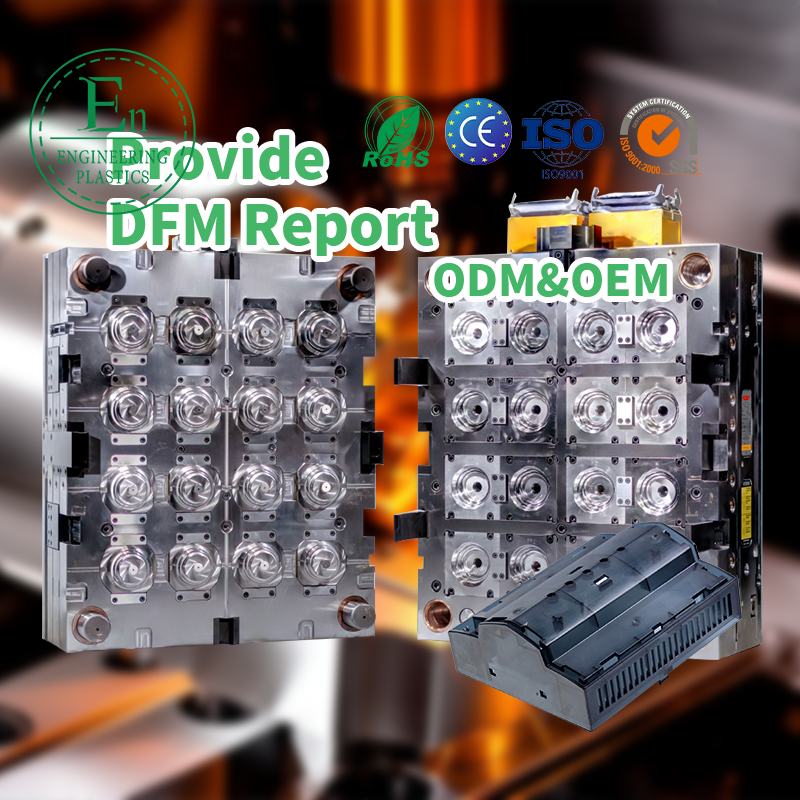

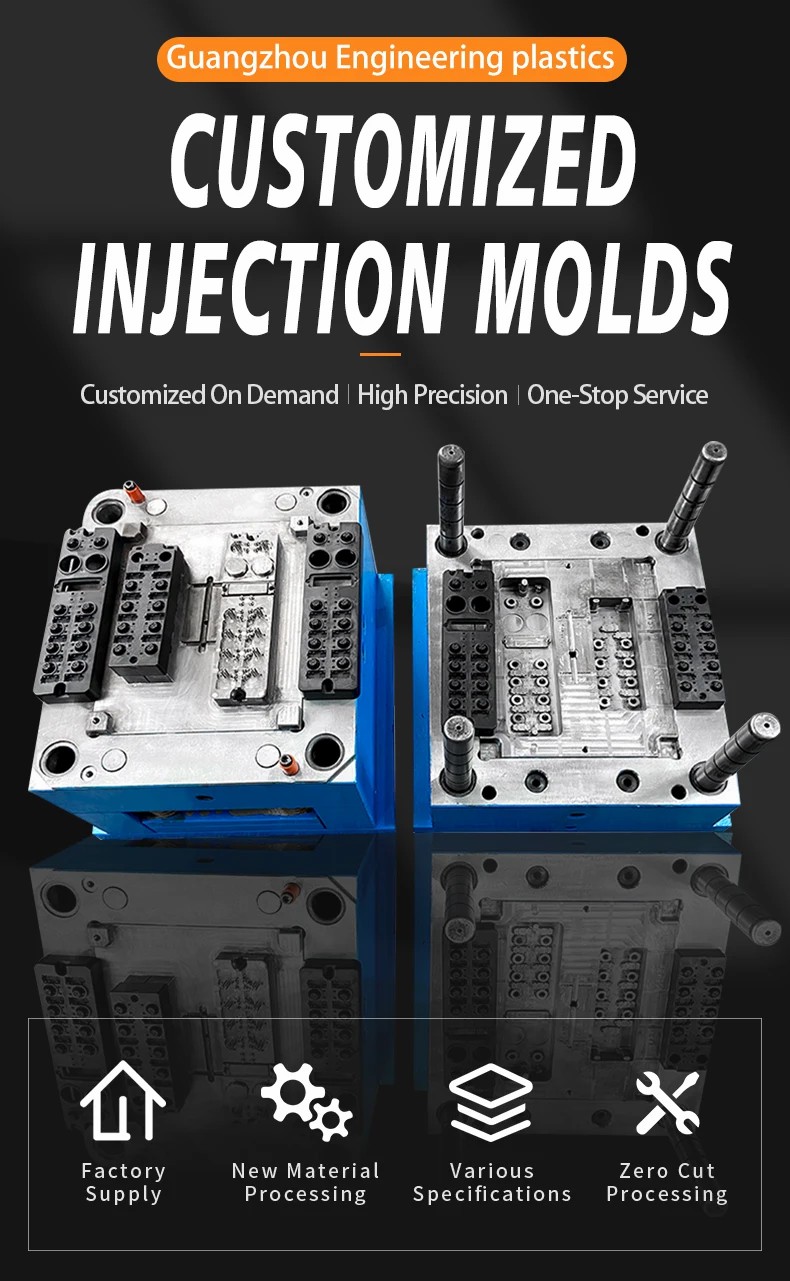

Assist global clients in engineering material,professional custom injection molding service,CNC machining service.We can provide you with one-stop solutions.

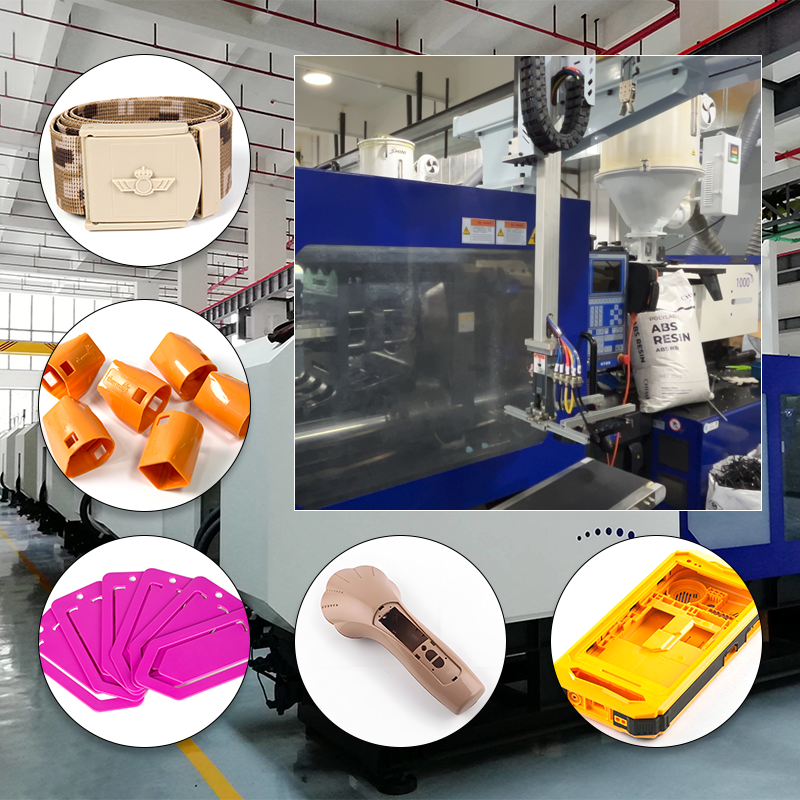

Those plastics materials like UHMW-PE , MY Nylon , PA6 , POM , HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic , PEEK , PPS , PTFE , PVDF , PAI , PEI , PSU , PI , PBI etc., they have different characteristic ! For example flowing temperature , crystallization speed , heat dispense , viscosity , pressure, speed , deformation and stripping .

Thanks for clients all along support , we gain lots of successful and failure cases , those experiences we store in database , which guide our new staff avoid same mistake. Today our comprehensive service from industrial design, mold design and manufacturing, volume production and production is based on an end-to-end quality assurance system that delivers an efficient, cost-saving, turnkey solution in plastic injection molding manufacturing.

Our mold team uses the lasted new version software design programs: UG, ProE, SolidWorks, Catia, Rhino etc., you can send any type of drawings xmt,step,vad or .iges. We also give you service is reverse engineering, we can follow your sample to create a completely new 3d drawings and the molds.

Our clients include medical industry, automobile, electronics industry, consume plastic products, etc., Our skilled technician and mould maker specialists work with each individual client and use the best material available for each application, Guides your project through each phase of development to save you time and money. We will explain whole process efficiently in five main stages: the production of the technical preparation stage, the preparation stage of raw materials, parts and components processing stage, assembly and commissioning phase trial identification stage. It is clear and confident to achieve success .

Testing and evaluation of injection molding materials

Once a suitable injection molding material has been selected, it is imperative to conduct thorough testing and evaluation to ensure that it meets the desired performance standards. Various testing methods are employed to assess the mechanical, thermal, and chemical properties of the material, providing valuable insights into its suitability for the intended application. These tests help manufacturers identify any potential issues early in the design process, reducing the risk of costly errors during production.

Mechanical testing typically involves evaluating properties such as tensile strength, impact resistance, and hardness. These tests allow manufacturers to understand how the material will behave under stress and help ensure that it meets the necessary performance criteria. Additionally, thermal testing can provide insights into the material's heat resistance and thermal stability, which are critical factors for applications exposed to high temperatures.

Chemical resistance testing is also essential, particularly for products that will encounter various substances in their end-use environment. By exposing the material to specific chemicals and evaluating its performance, manufacturers can determine whether it will maintain its integrity and functionality over time. This testing is crucial for ensuring the safety and reliability of the final product, especially in industries such as automotive, medical, and consumer goods.