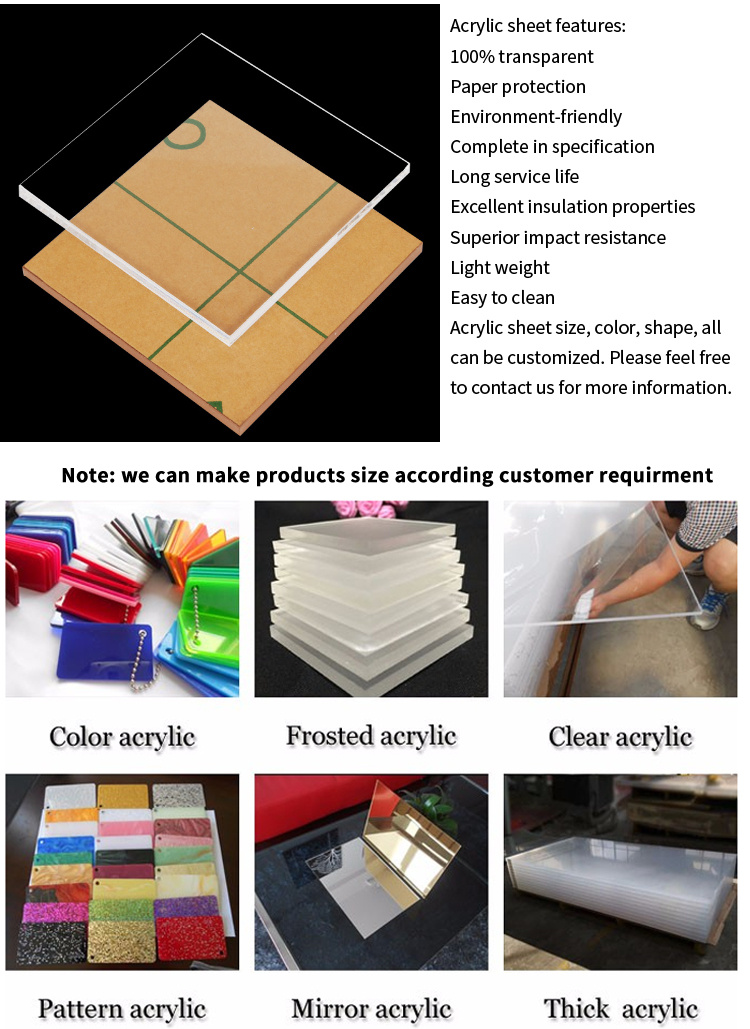

Heat resistant iridescent acrylic boar 100mm 100 300mm 500mm thick tinted acrylic plastic sheet acrylic sheets for laser cutting Prduct Display Advantages of acrylic thick plate 1. Durability: Acrylic thick plates are highly durable and res

acrylic tube aquarium large diameter acrylic tube solid acrylic tube

Heat resistant iridescent acrylic boar 100mm 100 300mm 500mm thick tinted acrylic plastic sheet acrylic sheets for laser cutting

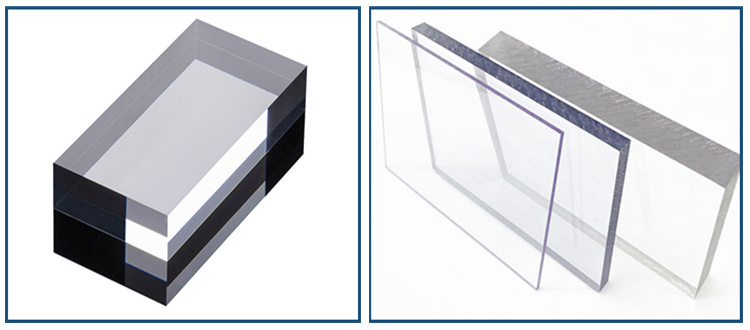

Prduct Display

Advantages of acrylic thick plate

1. Durability: Acrylic thick plates are highly durable and resistant to breakage, making them ideal for use in high-traffic areas.

2. Lightweight: Acrylic thick plates are lightweight, making them easy to handle and install.

3. Clarity: Acrylic thick plates have excellent clarity, making them ideal for use in applications where transparency is important.

4. UV resistance: Acrylic thick plates are highly resistant to UV rays, making them ideal for outdoor use.

5. Chemical resistance: Acrylic thick plates are resistant to many chemicals, making them ideal for use in industrial applications.

6. Easy to fabricate: Acrylic thick plates are easy to fabricate, making them ideal for use in a wide range of applications.

7. Cost-effective: Acrylic thick plates are cost-effective compared to other materials such as glass, making them an affordable option for many applications.

8. Versatile: Acrylic thick plates can be used in a wide range of applications, from signage to protective barriers to aquariums.

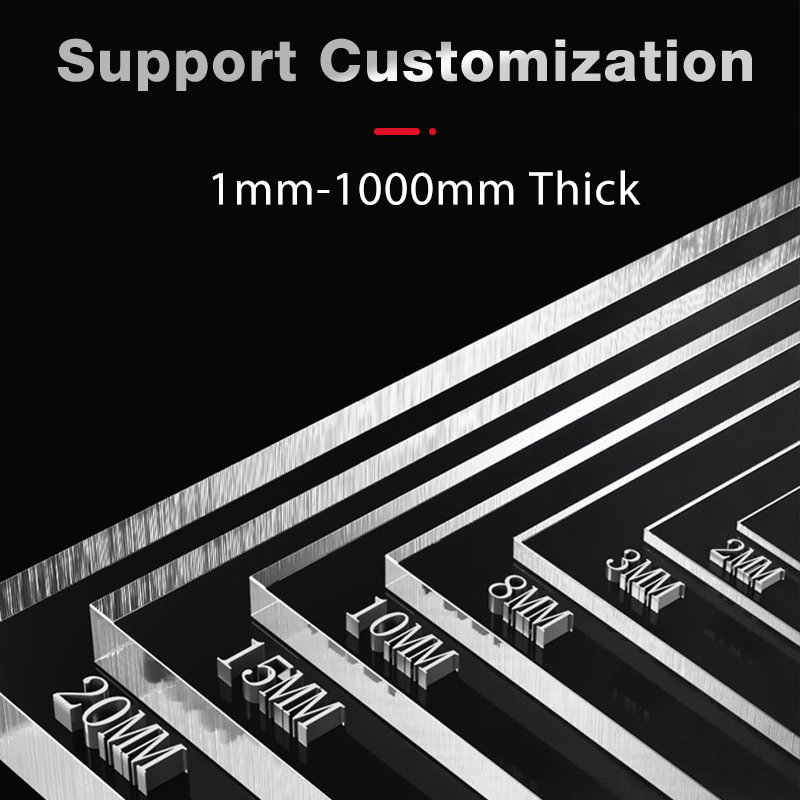

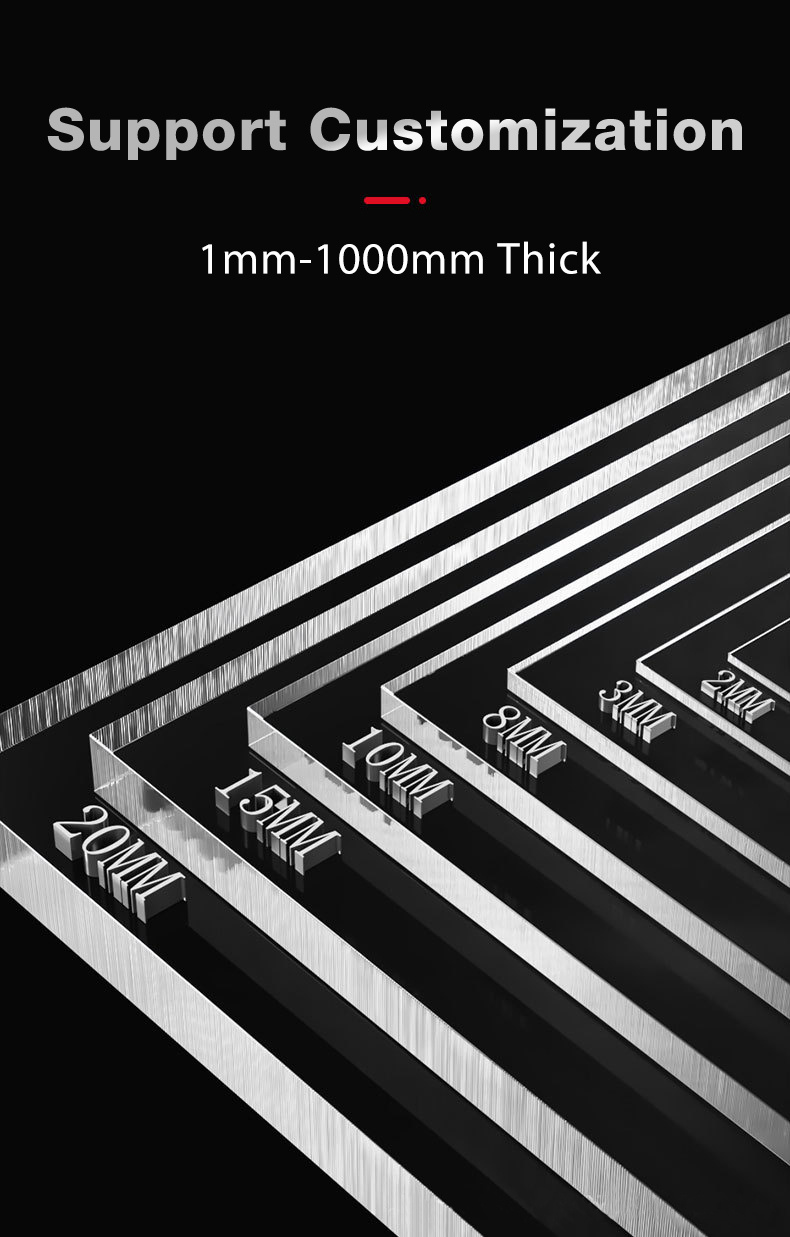

Prouduct Parameters

|

Product type

|

PMMA Tubes and Pipes/Acrylic Tubes/Plexiglass Tubes

|

|||

|

Material

|

PMMA,Acrylic

|

|||

|

Density

|

1.2g/cm3

|

|||

|

Diameter

|

8mm-500mm

|

|||

|

Thickness

|

1-100mm

|

|||

|

Length

|

2000mm, any custom length

|

|||

|

Color

|

clear/transparent, white, milky white, red, black,blue, fluorescent etc, any customized color

|

|||

|

Packing

|

covered with PE film

|

|||

|

Certificate

|

ISO9001,CE

|

|||

|

MOQ

|

100kgs (negotiable when we have in stock)

|

|||

|

Payment

|

T/T, L/C, Western Union, Paypal

|

|||

|

Delivery

|

7days

|

|||

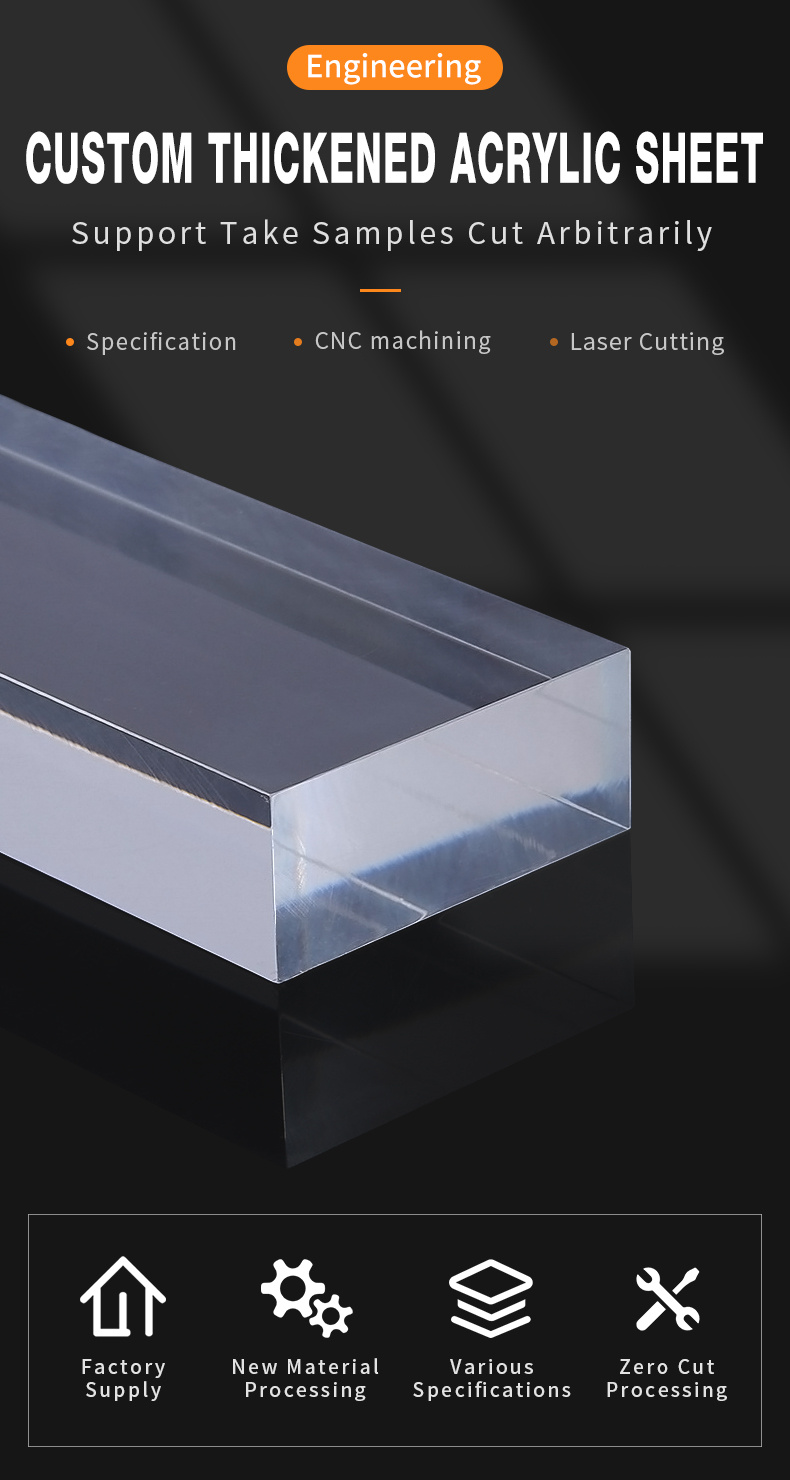

Product specification

Product Characteristics

01 Super impact resistance and high temperature performance outstanding

02 High surface hardness and excellent scratch resistance

03 Surface resistance value is 106 ~ 108Ω, with excellent anti-static function

04 Beautiful appearance, smooth, antistatic PMMA board light transmittance of more than 83%

05 Flame retardant grade for UL-94: V-0~V-2, fire performance is also very good

06 Color: transparent, blue transparent, yellow transparent, smoke gray transparent and so on...

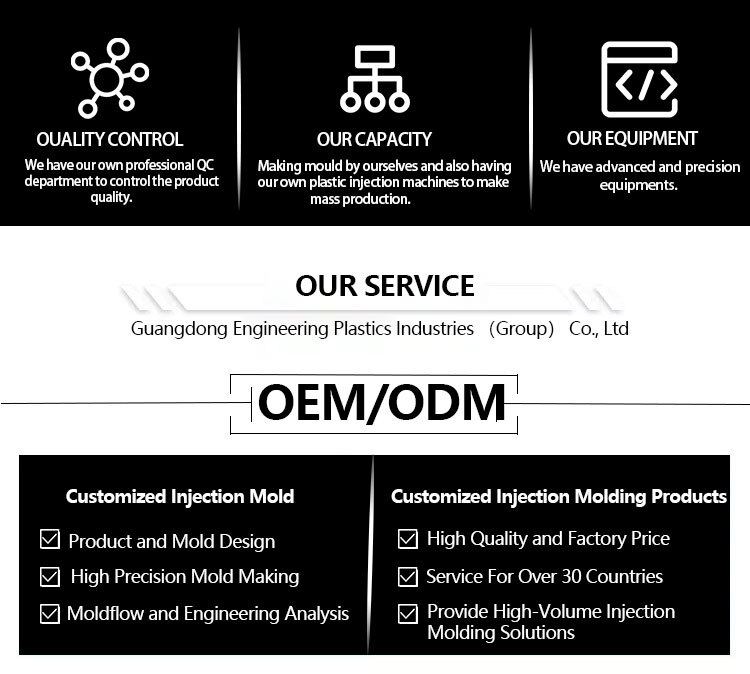

CUSTOMIZED SERVICE

1.Different thickness, size,color, surface ,shape OEM for you.

2.We can customize all kinds of Engineering plastics products according to customers'drawings or samples.

How To Customize

NO.1 Mailing samples

Our engineers can measure the specifications and test the materials to make an identical product based on the sample you provide.

NO.2 Provide drawings

We support CAD drawings, PDF files, STP, STEP,X-T and

other 3D formats for customization and confidential

processing of products according to your needs.

NO .3 Only photos

If you only have photos and no detailed drawing samples we can also process and make products for you if you provide us with the detailed dimensions of your products.

Application

We have a professional engineer team to design custom parts for your needs , we also have ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

If you have any problems or want to get the quoted price of any plastics or machined components, please feel free to contact us. Our engineers will reply to you as soon as possible.

A wide range of injection mold options

Our products cover auto parts mold, electrical appliances injection mold, medical machinery and so on. We provide products and services to more than 60 countries and regions in the world, including Europe, the United States and Southeast Asia.

Our Factory

Advanced plastics processing equipment Support variety processing methods.

Our factory has 100 sets of precision processing equipment, welcome to visit our factory!

The factory covers an area of 10,000 square meters Production equipment has the original American imported Haas CNC machining center, wire-electrode cutting, electrical discharge machine,Perforating machine, injection molding machine, CNC milling machine,CNC hobbing machine, CNC lathe, CNC milling machine, CNC lathe, CNC milling machine, grinding machine and other machinery and equipment.

One-stop Service

OEM, ODM, Customization service,Reasonable and competitive price,Design for Manufacturability (DFM) analysis with every quote,Short Delivery Time.

Reliable mold expert 15+ years' experience, Cooperated with many world famous brands for many years, Specialize in large and complex injection mold making, One-stop service from design to production.

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Professional team

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Client Witness

Our Exhibition & CCTV Interview

Buying Instructions

Q1. Can samples be produced?

A1. Yes

Q2. What is the accuracy of the products processed by the drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, molding

machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company's certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.