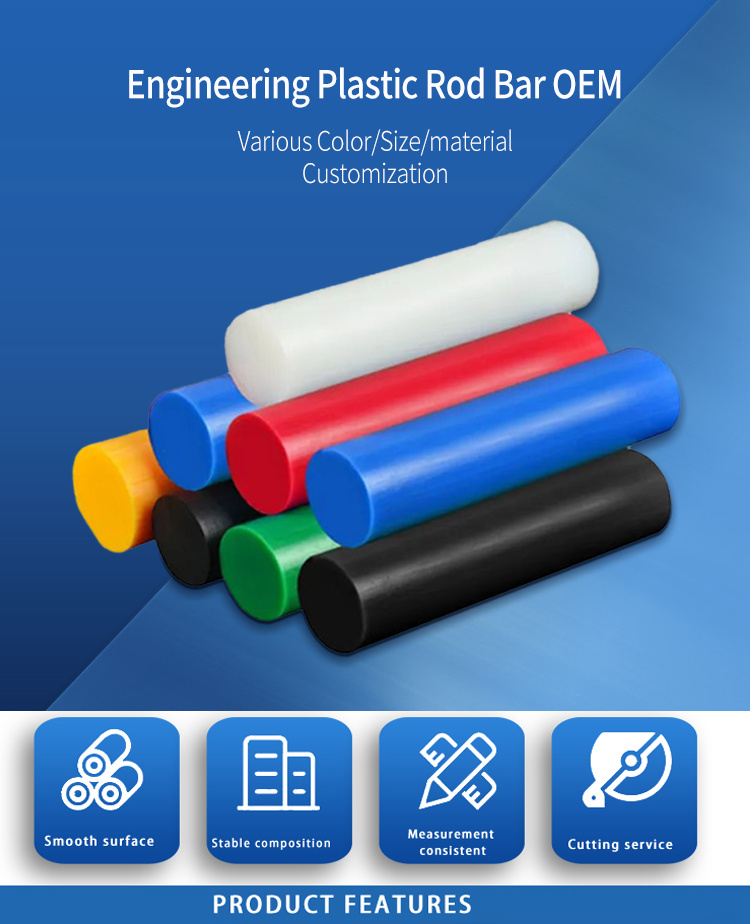

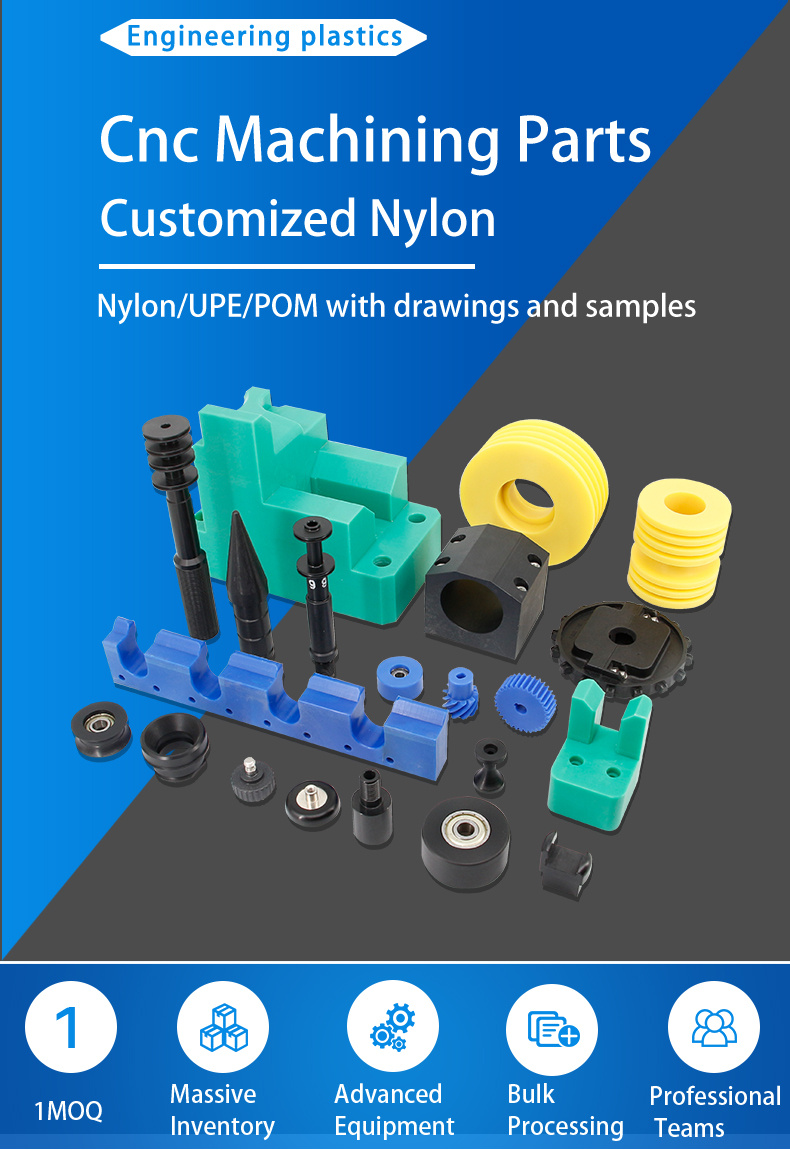

Good Tensile Strength Cast PA Plate Nylon Board PA66 Sheet 10mm Panels UHMWPE/HDPE/PP plastic sheet 1.We can be made of MC Nylon/ PA6,PP (polypropylene), PE (polyethylene), PA (nylon), POM (polyoxymethylene), ABS, PVC (polyvinyl chloride) PC (pol

injection molding General Engineering plastics-plastic injection molding General Engineering plastics-Mold injection molding General Engineering plastics

Good Tensile Strength Cast PA Plate Nylon Board PA66 Sheet 10mm Panels UHMWPE/HDPE/PP plastic sheet

1.We can be made of MC Nylon/ PA6,PP (polypropylene), PE (polyethylene), PA (nylon), POM (polyoxymethylene), ABS, PVC (polyvinyl chloride) PC (polycarbonate). The color and size of engineering plastic sheet can be customized.

2.Product Material: UHMW-PE、MC Nylon、PA6、 POM、HDPE、 ABS. PU.PC、PVC、PP、PET、PBT、Acrylic、PEEK、PPS、 PTFE、 PVDF、PAI、 PEI、 PSU. PI、PBI、Antistatic product series company wide range of accessories processing conditions.

Product Advantages: all made of pure new materials, the product is non-toxic and tasteless, in line with food grade, smooth appearance and no impurities.

PA6, PA66, MC NylonMaterial

PA: Nylon is a ductile horny translucent or milky white crystalline resin. As a engineering plastic, the molecular weight of nylon is generally 1.5 to 30,000. Nylon has high mechanical strength, high softening point, heat resistance, low friction coefficient,abrasion resistance, self-lubricating property, shock absorption and sound absorbing property, oil resistance, weak acid resistance, alkali resistance and general solvent, and good electrical insulation. Self-extinguishing, non-toxic, odorless,weather resistant, and poor dyeability.

UHMW-PE Material

UHMW-PE is a thermoplastic engineering plastic with the average molecular weight more than 9.2 million. This kind of material with five top performance of high-wear-resistance,good-chemical resistance, low-temperature resistance,self-lubrication and high-impact resistance, which is regarded as a surprised" engineering plastic of excellent comprehensive capacity and competitive price.

POM Material

ABS plastic sheet is the most widely used engineering thermoplastic today, which is formed by the polymerisation of styrene and acrylonitrile on to thermoplastic rubber which is then melt compounded with styrene acrylonitrile. Guangzhou Engineering Plastics Industries (Group) Company has studied and applied this material in many industries for many years. And we know that it has the following main properties.

HDPE Material

HDPE is a semi-crystalline, thermoplastic engineering material with high toughness and good low temperature properties.We has studied and applied this material in many industries for many years. And we know that it has the following main properties. The main characteristics of HDPE are: Tough; Very low water absorption; Good sliding properties; Resistant to dilute acids,cleaning agents, numerous solvents; Very good electrical insulation; Difficult to bond; Easily welded; Low density.

ABS Material

ABS plastic sheet is the most widely used engineering thermoplastic today, which is formed by the polymerisation of styrene and acrylonitrile on to thermoplastic rubber which is then melt compounded with styrene acrylonitrile. Guangzhou Engineering Plastics Industries (Group) Company has studied and applied this material in many industries for many years. And we know that it has the following main properties.

PP Material

PP is a semi-crystalline, thermoplastic engineering material with high toughness and good chemical resistance. PP also offers good thermal and electrical insulation and is also resistant to many acid, alkalis and organic solvents making it an ideal choice for fabrication jobs in chemical and effluent treatment plants.

PEEK Material

PEEK is a kind of heat-resistant, high performance

thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasionresistance, and hydrolysis resistance properties etc. It has a light proportion and self-lubricating properties. Due to very

good processing properties, it can be filled with carbon fiber,Fiberglass and MoS2 etc. In order to improve lubrication performance and mechanical strength further.

Antistatic PVC Material

Antistatic PVC sheet is also called ESD PVC Sheet with basic material PolyvinyIChlo-ride (Short form: PVC). Guangzhou Engineering Plastics Industries (Group) Company has studied and applied this material in many industries for many years. And we know that Antistatic PVC Sheet has an High Antistatic Resistant, exceptional chemical resistance and has high mechanical and tensile strength - combined with a high degree of stability which together makes this easily welded product one of the most versatile general purpose plastics available.

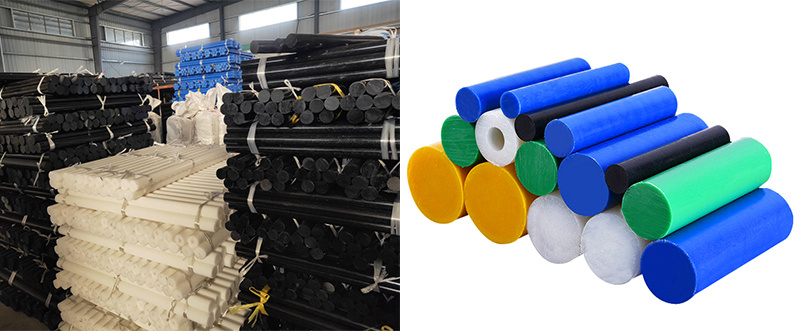

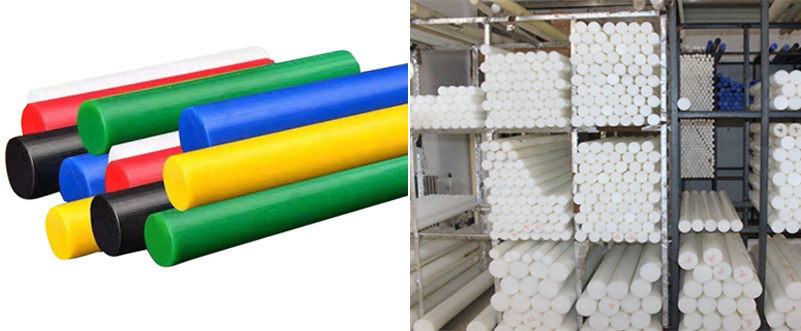

Guangzhou Engineering Plastics Industries (Group) co., LTD., established in January 2009,is a professional production of "engineering plastics accessories" high-tech enterprises. The company has a complete set of imported production equipment and numerical control processing equipment, processing means is advanced, technical force is abundant. Product best-selling Europe and America, southeast Asia, the Middle East, Africa and Hong Kong, Taiwan and other countries and regions, by domestic and foreign customers consistent high praise.Company's main products:UHMW-PE、MC Nylon、PA6、 POM、HDPE、 ABS. PU.PC、PVC、PP、PET、PBT、Acrylic. PEEK. PPS、 PTFE、 PVDF、PAI、 PEI、 PSU. PI、PBI、Antistatic product series company wide range of accessories processing conditions, such as mass customization production ability, exquisite manufacturing technology and advanced production equipment, professional technical advice and after- sales service of products.Companies strictly enforce the ISO9001 (2008) international quality certification system,

the product quality conforms to the eu RoHS standard.

Certificate

Engineering Plastic Board Sheet ODM/OEM ONE-STOP SERVICE

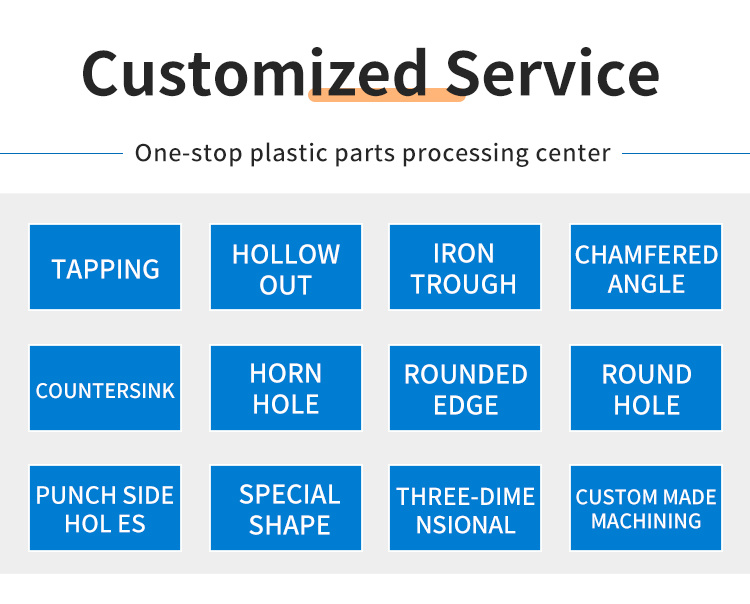

●Our Service: Plastic Injection molding,CNC machining service,High performance plastic solutions ,Free design modifications, etc.

●Our Production Equipment: High-precision CNC molding manufacture machines, High-accuracy EDM machines, High-precision mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines, Double color injection machines, fine carving machines, Horizontal lathes, milling machines, etc

●Our engineering plastics products: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

|

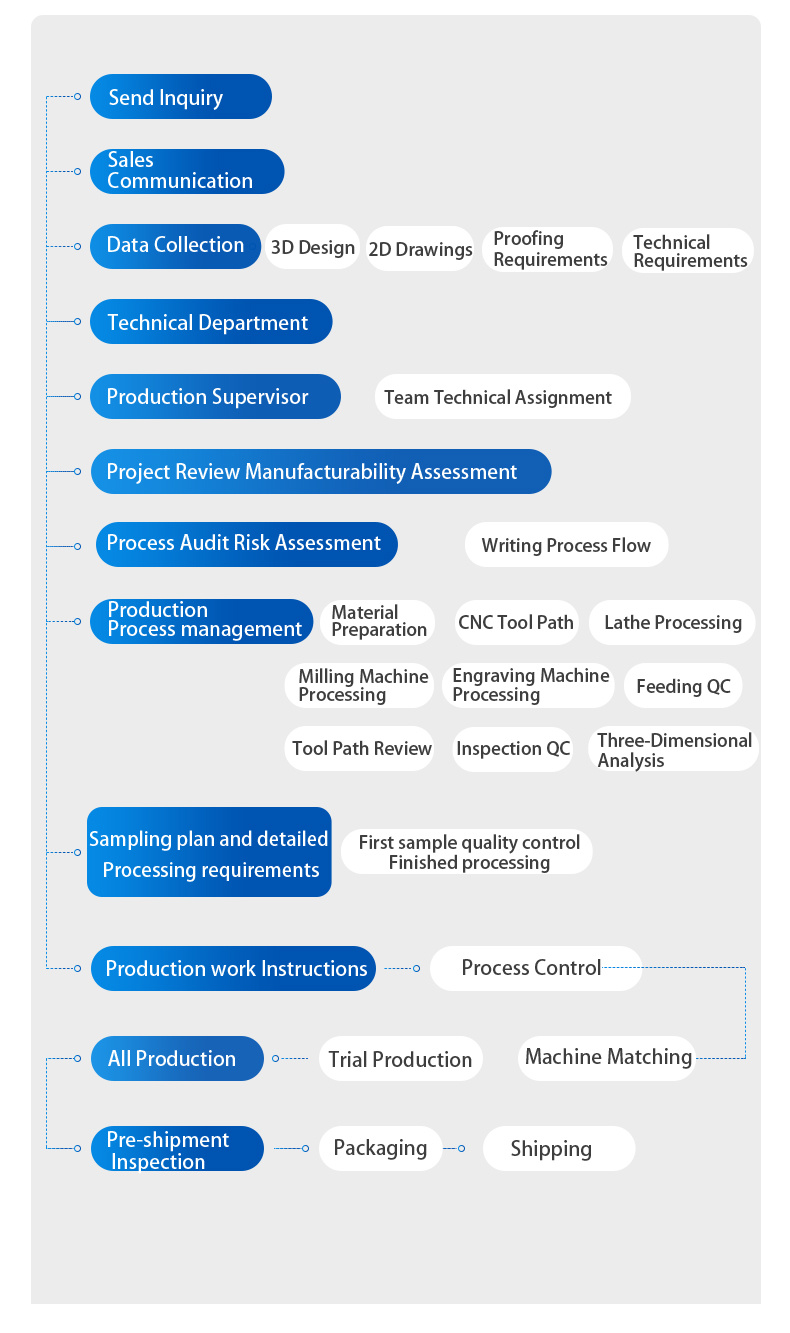

Custom CNC Machining Parts Services

|

||||

|

Quotation

|

According to your drawing(size,material,thickness,processing content,and required technology,etc)

|

|||

|

Material

|

Metal: Stainless steel, aluminum alloy, brass, steel;Plastic:ABS, Nylon, PC, Pvc,etc

|

|||

|

Process

|

CNC Milling, CNC Turning, Auto lathe,Drilling Laser Cutting,etc

|

|||

|

Surface

|

Treatment Powder coating, anodizing, polishing, electroplating,etc

|

|||

|

Processing equipment

|

CNC lathe, CNC milling machine, drilling machine; Core machine, Cutting machine

|

|||

|

Accept drawings

|

CAD (DXE.DWG), PDF, Pro/Engineer

|

|||

|

Tolerance

|

+/-0.02mm

|

|||

|

Quality Assurance

|

ISO9001:2015

|

|||

|

Delivery time

|

1-2 weeks for samples, 3-4 weeks for mass production

|

|||

|

Payment

|

TT, Trade Assurance, Paypal, WestUnion

|

|||

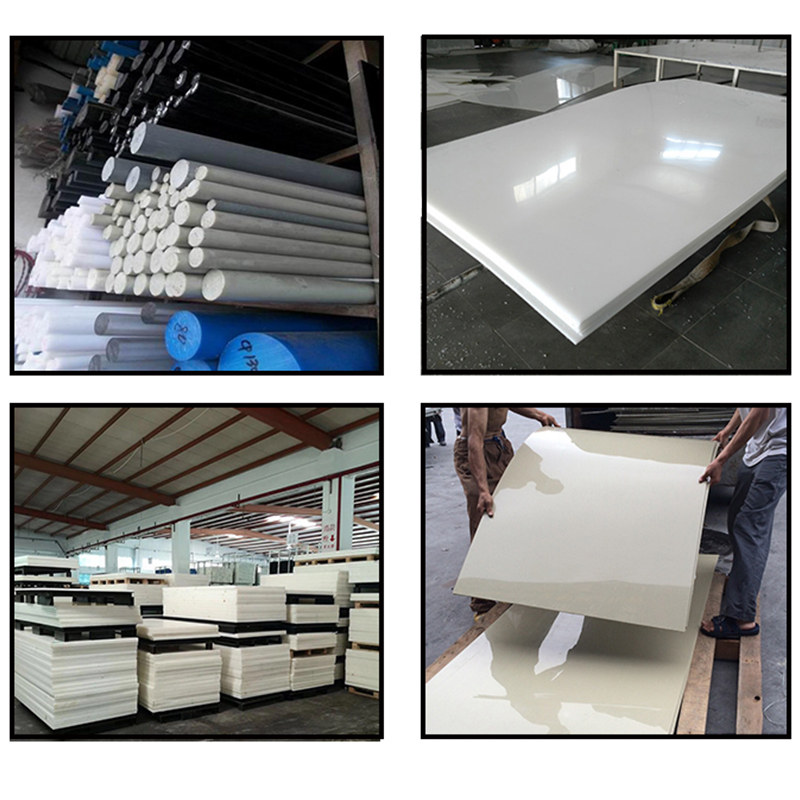

Our Factory