|

|

In the production of plastic products, custom injection molds and hand model models are widely used, but what is the difference between them? Injection molding manufacturers suggest that you can distinguish between the following aspects.

The hand board is usually made of plastic or metal on the engraving machine or in the form of 3D printing or multi-mode, making several samples or small batch production. The mold opening refers to the first processing of the mold, and then the injection molding of the mass production of the product. Generally, the customer will confirm the hand plate first, and then open the mold for mass production after confirmation.

Shouban is a sample of the product. When your design drawings come out, the finished product can\'t be perfect or even can\'t be used. Direct production will be scrapped once it is defective, which will waste manpower and material resources and time. , the loss of manpower and material resources, quickly find out the lack of product design and improve, to provide sufficient basis for product stereotypes.

CNC machining: CNC machining is processing using CNC equipment such as engraving machine. It is the mainstream processing method in the hand board industry. The processing materials are not particularly limited. Basically, plastic, aluminum alloy sheet, foam, foam, etc. can be realized.

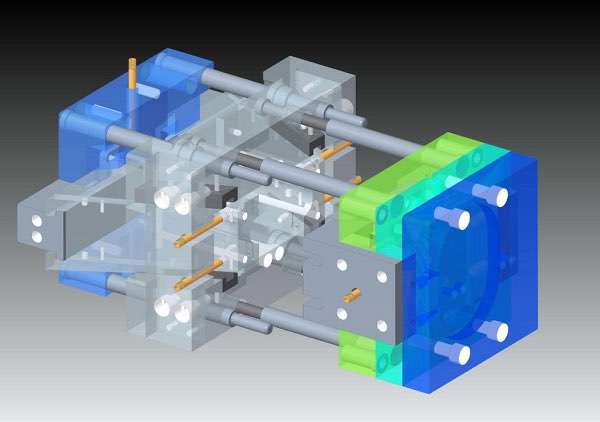

The mold is a metal mold for each plastic and metal part after the hand piece is confirmed. It is a tool that can produce parts with certain shape and dimensional accuracy requirements. Generally, it is a steel mold. The requirements for machine tools and tools are much higher than that of the processing hand. The processing cost is also much higher. The common items such as TV sets, telephone casings, plastic barrels, etc., are used to heat the plastic into the mold for cooling. Produced out.

Injection molding manufacturers believe that the injection mold and the hand model are also related. Generally, the shape is confirmed by the hand model to the customer, and then the mold is mass-produced after confirmation. The cost of mold manufacturing is very high, especially for large molds such as medical and automotive, which are worth hundreds of thousands or even millions. If there is structural irrationality or other problems in the process of making the mold, the risk is great. The hand model can solve this problem well and reduce the danger of mold opening.

If you need custom injection molding, please contact us.

|

|