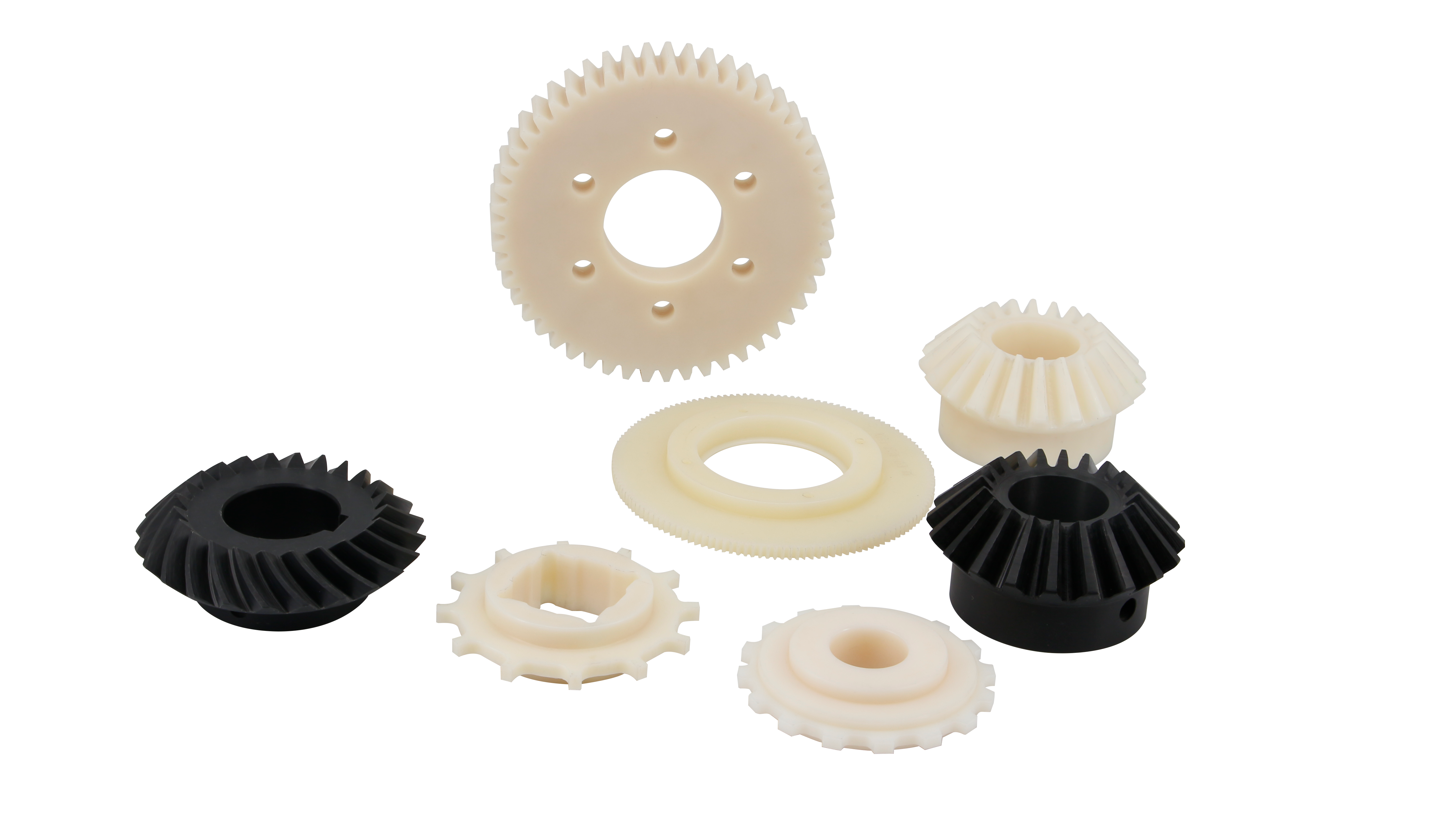

Advantages of plastic gears include light weight, no rust, no noise, injection molding enables low-cost and high-volume production, and can run without lubrication by mating with metal gears. On the other hand, it has lower strength than metals, tends to

Machined gear

Product Paramenter

Advantages of plastic gears include light weight, no rust, no noise, injection molding enables low-cost and high-volume production, and can run without lubrication by mating with metal gears. On the other hand, it has lower strength than metals, tends to generate heat, and has large dimensional changes such as backlash. The degree of dimensional change of plastic gears depends on the ability to resist temperature changes, moisture absorption rate and chemical resistance, and the use of each field is different. We can also customize metal gears according to your drawings or samples.

|

Products |

Gear |

|||

|

Module |

M0.5-M10 |

|||

|

Precision grade |

DIN6, DIN7, DIN8, DIN10 |

|||

|

Pressure angle |

20 degree |

|||

|

Material |

C45 steel, Stainless steel 304, Plastic, Brass, 20CrMo,40Cr and so on |

|||

|

Heat treatment |

Hardening and Tempering, High Frequency Quenching,Carburizing etc |

|||

|

Surface treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|||

|

Application |

Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems.Automated warehousing systems. |

|||

|

Machining process |

Hobbing, Milling, Drilling, Shaving, Grinding |

|||

Descriptions:

(1) According to the different strength and performance, we choose the steel with strong compression;

(2) Using Germany professional software and our professional engineers to design products with more reasonable size and better performance;

(3) We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;

(4) Quality assurance in every step to ensure product quality is controllable.

Prduct Display

●Our Service: Plastic Injection molding,CNC machining service,High performance plastic solutions ,Free design modifications, etc.

●Our Production Equipment: High-precision CNC molding manufacture machines, High-accuracy EDM machines, High-precision mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines, Double color injection machines, fine carving machines, Horizontal lathes, milling machines, etc.

●Our engineering plastics products: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

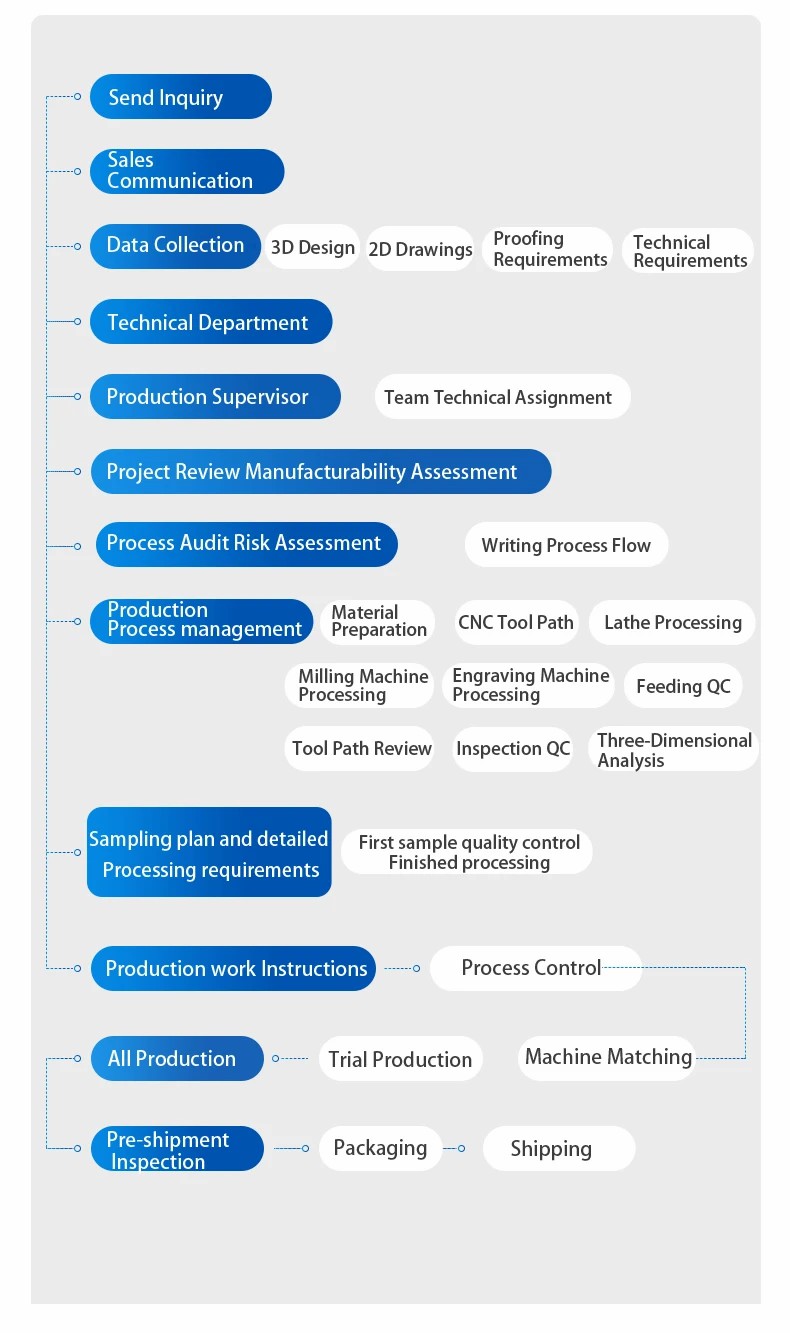

Customized Service

Please send us your complete list of requirements and we will be more than happy to start discussing in detail how to implement these requirements into the final product.

NO.1 Mail Samples

Customized samples, our engineers can make exactly the same products according to the samples you provide,measure the specifications and test the product materials.

NO.2 Provide Drawings

We support CAD drawings, PDF files, 3D formats for customization, such as STP, STEP, X-T, etc.Confidential handling of products according to your needs.

NO.3 Provide Photos

If there are only photos and no detailed drawings and samples, you can provide detailed size specifications of the product, and we can also help you process and produce the product.

Our Factory

Guangdong Engineering Plastics Industries Co., Ltd! We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design, research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines, such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

Certification